Vertical Mill Liners

Vertical Mill Liners

Vertical Mill Liners|Customized Wear Solutions for Efficient Fine Grinding & Cost Reduction

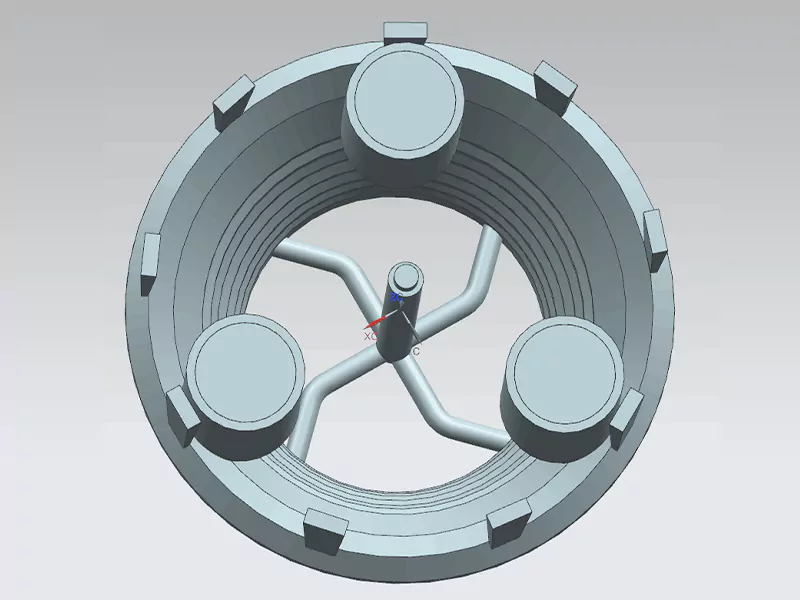

Vertical mills are core equipment in modern mineral processing, widely used for the fine grinding of materials such as cement raw meal, clinker, coal, and metallic ores. Huasheng is a specialist manufacturer of high-wear-resistant liners for vertical mills. We offer standard materials including ZG Mn13Cr2, ZG Mn18Cr2, ZG Mn22Cr2, and high-chromium cast iron series. Backed by extensive field application experience, we provide cost-effective, personalized liner solutions tailored to specific material characteristics and operational conditions. Additionally, we develop composite material solutions, combining high-manganese steel or high-chromium iron bases with advanced ceramic or carbide inserts for extreme abrasion zones.

As a manufacturer focused on mining and cement industry wear parts for over 14 years, Huasheng provides global vertical mill users with wear-resistant, cost-optimizing solutions. Targeting the high-abrasion working conditions of materials like clinker, slag, and various ores during fine grinding, we integrate our full range of material technologies—from premium high-manganese steels to high-chromium cast irons and composite designs. Through precise process control in casting and heat treatment, we ensure optimal microstructure (grain size controlled to levels 2.5-4 per GBT6394) and hardness profile. Proven by numerous field applications, our liners contribute to a more stable grinding bed, improved grinding efficiency, reduced specific energy consumption, and an average increase in liner service life of 30-80%, effectively helping lower overall operating cost per ton of product.

Huasheng is more than a parts supplier; we are your grinding process partner. Our technical team offers comprehensive support from initial liner profile design and material selection to performance analysis and maintenance interval optimization, ensuring your vertical mill achieves maximum availability and profitability.

Inquiry

Our Products

Advantage

Raw material control

Customized

Rich experience

Quality inspection

Process

1.Process design

2.Pattern Making

3.Modeling

4.Coating

5.Casting

6.Pouring

7.Clean

8.Heat Treatment

9.Grinding workshop

10.Machining

11.Inspection