Shovel Undercarriage Parts

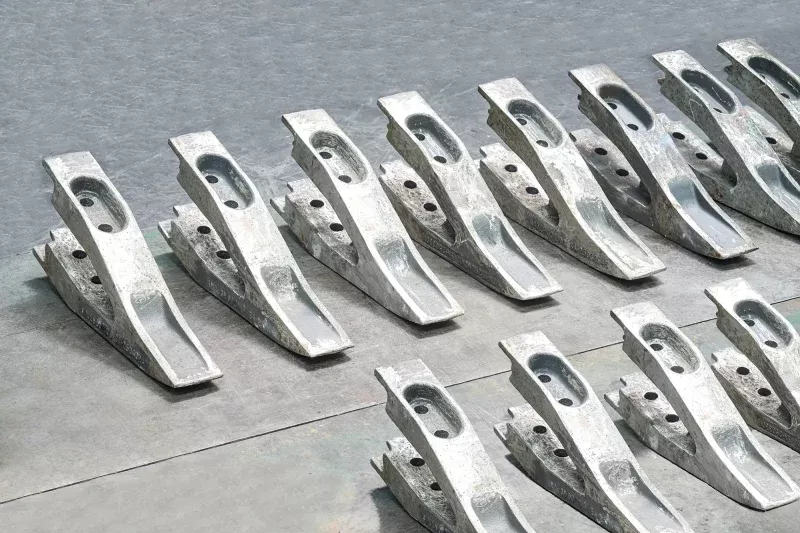

High Manganese Steel Alloy Steel Shovel Undercarriage Parts

Shovel Undercarriage Parts

Shovel Undercarriage Parts Electric shovels and hydraulic shovels are large-scale, high-efficiency, heavy-duty core excavation equipment in construction machinery. With their strong digging force, flexibility, and versatility, they play a key role in many fields, mainly used in: open-pit mining (core application), large-scale earthwork projects, aggregates/sand and gravel materials, etc. Huasheng is a manufacturer of accessories such as the four-wheel belt, bucket teeth, and bucket lips for this equipment, and can provide a full set of accessories for the world’s main models.

Material

- High manganese steel

- Alloy Steel

Inquiry

Our Products

Hydraulic Shovel Parameters

| TEREX/O&K/CAT | KOMATSU /DEMAG | HITACHI | LIEBEHERR |

| 5230 | PC3000 | EX2500 | R966 |

| RH120/6030 | PC4000 | EX3500 | |

| RH170/6040 | PC5500 | EX3600 | |

| RH200/6050 | PC8000 | EX5500 | |

| RH340/6060 | EX5600 | ||

| RH400/6090 | EX8000 |

Electric Shovel Parameters

| P&H/KOMATSU | BUCYRUS ERIE/CAT |

| 2300XPA/XPB/XPC | 495/7495B11 |

| 2800XPA/XPB/XPC | 495/7495HF |

| 4100ХPA/XPB/XPC | 495/7495HD |

| 4100XPCXXL |

Advantage

Raw material control

We control the quality of each batch raw material strictly.

Customized

We can produce various crusher frames and customize them according to the drawings for enterprises.

Rich experience

According to the operating characteristics of the crusher, improve the process and extend its service life.

Quality inspection

International Level II UT and MT inspection standards; Pay attention to improving the appearance quality of castings.

Process

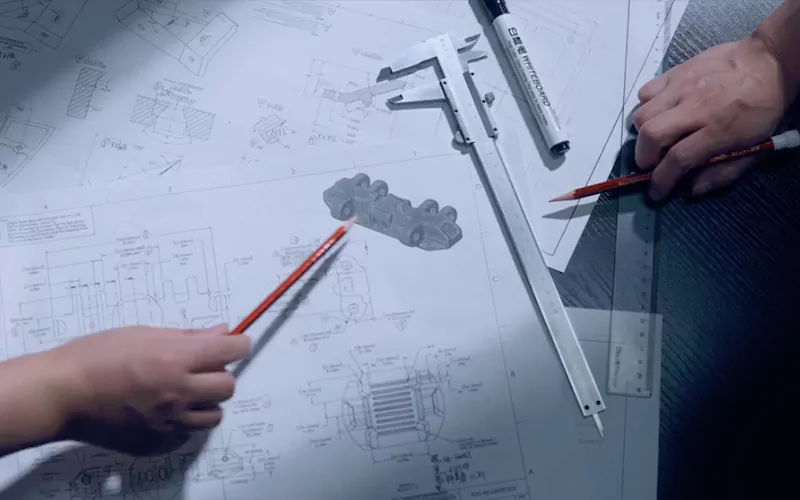

1.Process design

2.Pattern Making

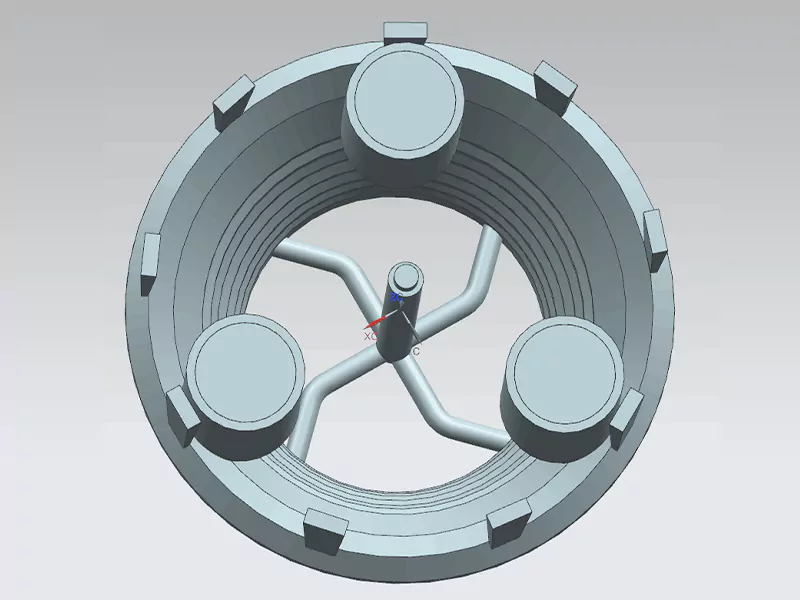

3.Modeling

4.Coating

5.Casting

6.Pouring

7.Clean

8.Heat Treatment

9.Grinding workshop

10.Machining

11.Inspection