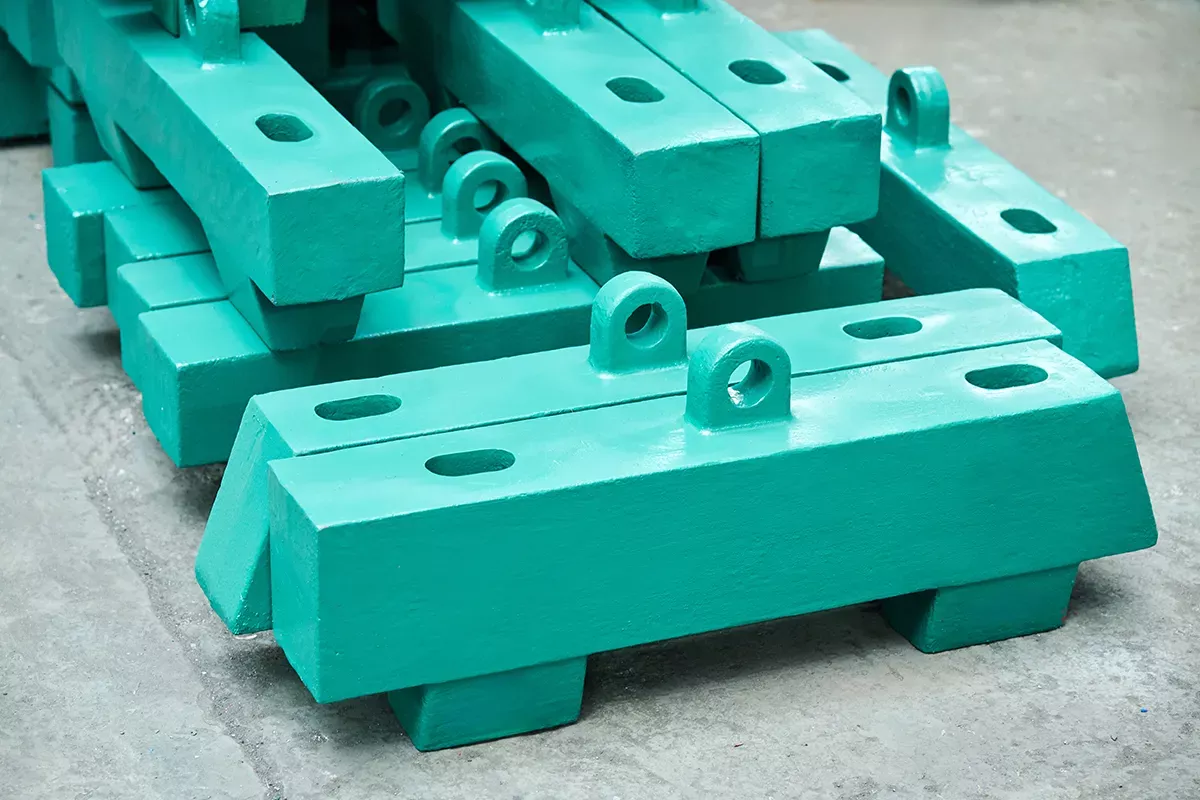

As a premier manufacturer of austenitic manganese steel castings in China, Huasheng Castings leverages 30+ years of metallurgical expertise to produce mill liners with exceptional service life. Our specialized manganese alloy solutions deliver superior performance in high-impact applications.

In solution-annealed and water-quenched states, manganese steel exhibits an initial hardness of ~220 HB. Through strain hardening under impact loading – while minimizing gouging abrasion – material hardness can increase to approximately 500 HB. In crushing environments dominated by gouging abrasion, practical hardening typically reaches 350-450 HB.

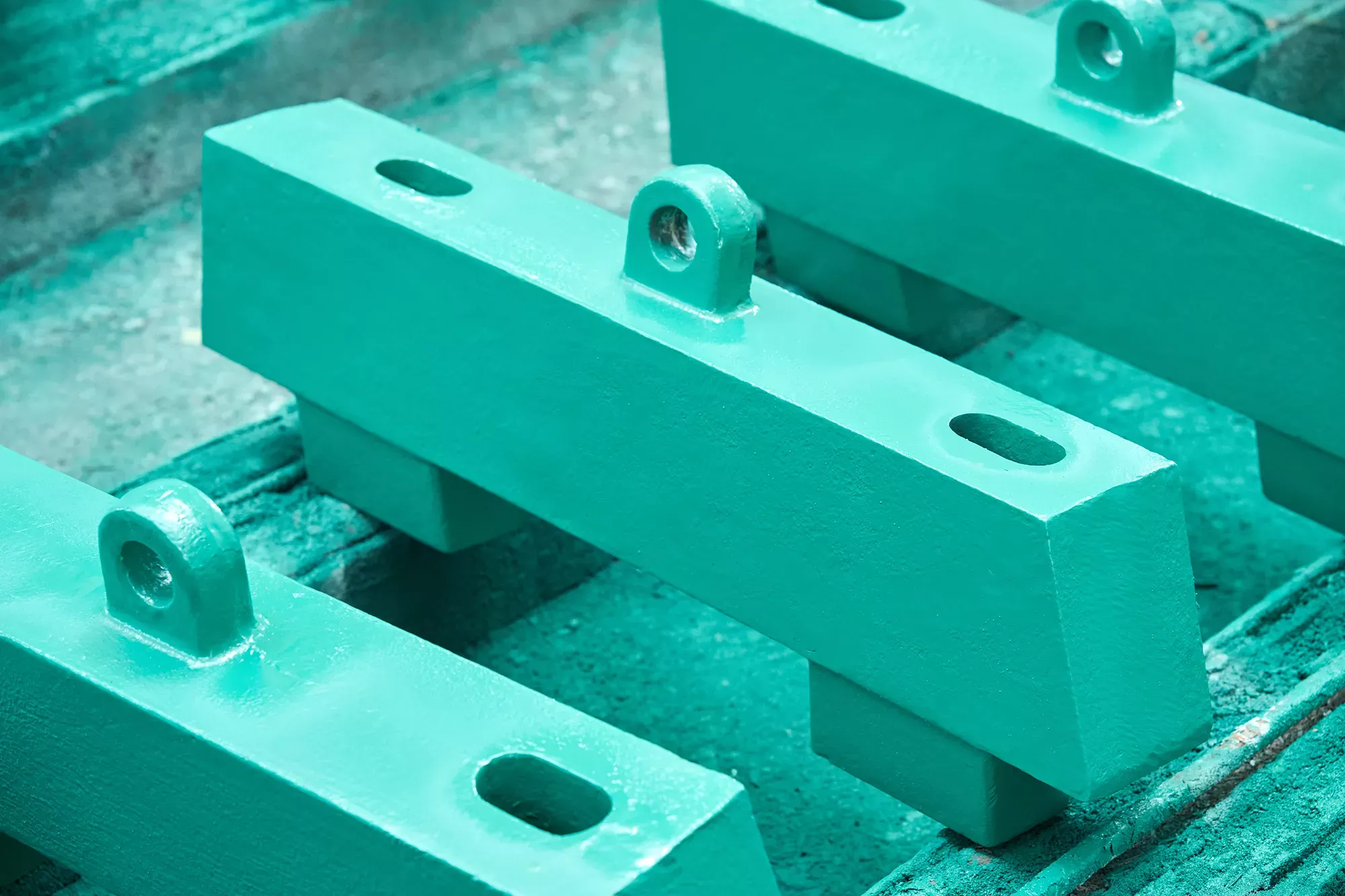

This material excels in grid liners and compact mills, where its unique work-hardening capability maintains substrate toughness under extreme impact. Critical note: Under sustained impact, manganese steel undergoes plastic deformation causing liner compression. This may result in:

Installation/removal challenges

Potential mill shell damage from accumulated stress

Proper engineering controls are essential to mitigate these effects.