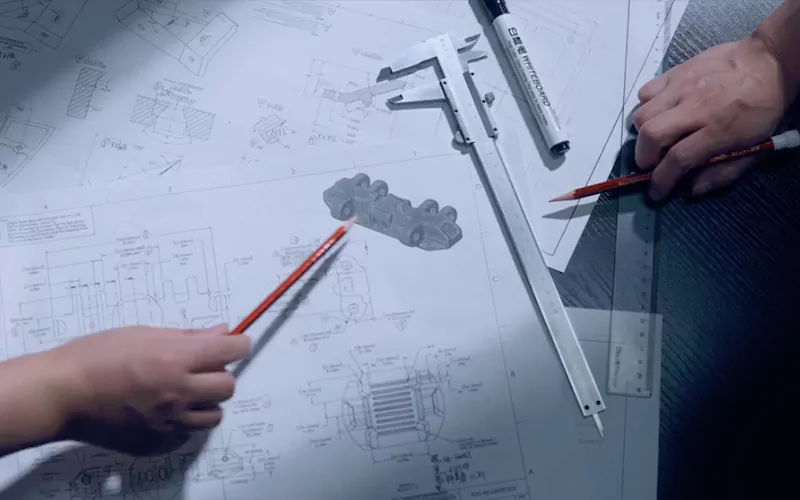

Huasheng Castings Undercarriage Parts for Electric Rope Shovels factory and suppliers,Heavy-Duty Undercarriage Components for Electric Rope Shovels,Ensuring maximum stability, mobility and durability in extreme mining conditions

Electric rope shovels are equipped with essential undercarriage parts that ensure stability, mobility, and durability during operation. Key components include the front idler, track pad, drive tumbler, rear idler, and lower roller, each designed to withstand harsh conditions and provide optimal performance.

1. Front Idler

Function: The front idler is primarily responsible for guiding the track and maintaining proper tension. It supports the weight of the front of the machine, ensuring smooth movement across various terrains.

Design: Typically made from highstrength steel, it features wearresistant and impactresistant properties to withstand harsh working environments.

Maintenance: Regular inspection of the front idler for wear is essential to ensure optimal operation and prevent track slack due to excessive wear.

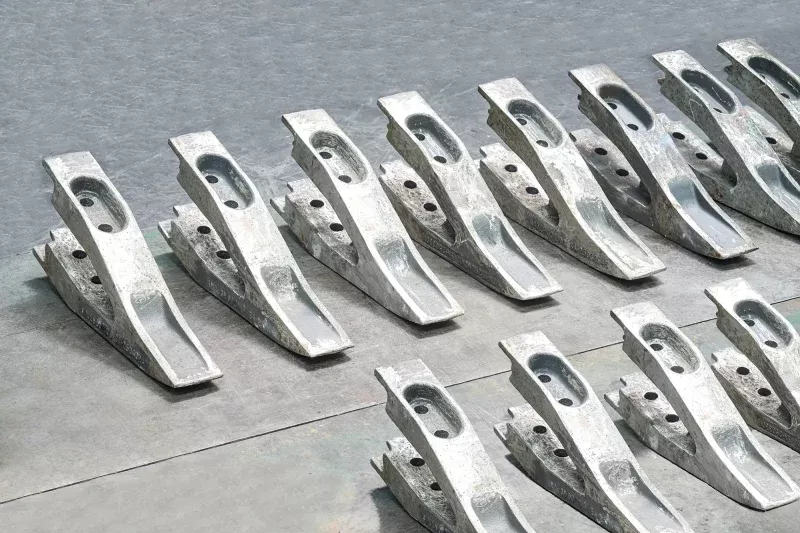

2. Track Pad

Function: The track pad is the surface that contacts the ground, providing stability and traction for the machine while effectively distributing its weight and minimizing ground pressure.

Design: Made from durable materials, it often includes a specialized tread pattern to enhance grip and durability. Different working environments may require different types of track pads.

Maintenance: Regularly check the track pads for wear and replace them as necessary to ensure optimal performance.

3. Drive Tumbler

Function: The drive tumbler is crucial for transferring power from the motor to the tracks, serving as the core component of the propulsion system and ensuring efficient movement and maneuverability of the shovel.

Design: It is typically constructed from wearresistant materials and designed to withstand significant loads and impacts.

Maintenance: Regularly inspect the lubrication and wear of the drive tumbler to ensure proper operation and avoid power loss.

4. Rear Idler

Function: The rear idler helps maintain track tension and supports the rear part of the crawler system, contributing to overall stability and balance during operation.

Design: Made from robust materials, it can withstand pressure from both dynamic and static states of the machine.

Maintenance: Regular checks for wear and damage on the rear idler are essential to prevent track issues.

5. Lower Roller

Function: The lower roller supports the track and helps distribute weight, ensuring smooth track movement and reducing wear on the track pads.

Design: It typically features high loadbearing capacity and wear resistance, designed to endure the stresses of operation.

Maintenance: Regularly inspect the lower rollers for wear and ensure they are properly lubricated to maintain performance and longevity.