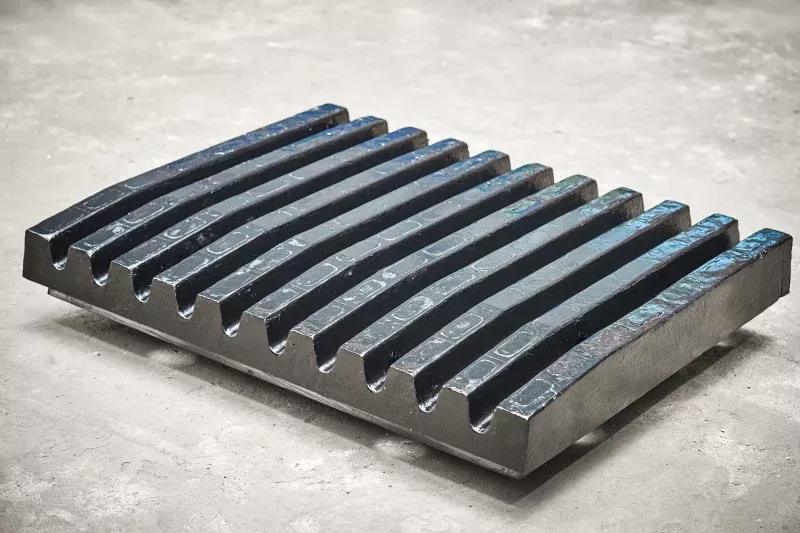

As a primary crushing workhorse and the preferred choice for mobile crushing stations, jaw crushers are subjected to extreme abrasion and impact. Huasheng’s cheek plates are specifically developed to meet the harsh challenges presented by high-abrasive materials like granite and basalt, as well as the frequent start-stop cycles typical in mobile crushing applications.

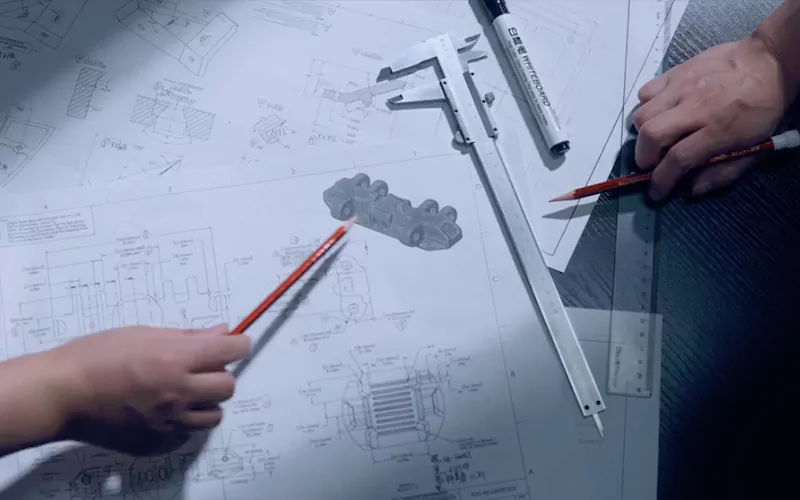

Cheek Plate Casting & Manufacturing Process

Our cheek plates are manufactured using advanced sand casting techniques and rigorous quality control processes, adhering to international standards.

- Material Expertise: Our primary materials include:

- ZG Mn13Cr2: A standard manganese steel offering excellent work-hardening capabilities and good impact resistance.

- ZG Mn18Cr2: A higher-grade manganese steel that provides superior work-hardening and abrasion resistance for more demanding applications.

- ZG Mn22Cr2: Our premium high-manganese steel grade, delivering the highest level of impact toughness and work-hardening properties for the most severe crushing conditions.

- Innovative Composite Solution: Beyond standard materials, Huasheng offers a groundbreaking composite solution. This involves a high-manganese steel base mother material, into which highly wear-resistant Titanium Carbide (TiC) alloy bars and High-Chromium alloy blocks are strategically embedded. This technology creates a component with the unparalleled toughness of manganese steel and the extreme wear resistance of hard alloys, significantly extending service life in the most abrasive environments.

- Jaw Crusher Wear Parts Cheek Plate Package

Performance & Key Features

- Superior Impact Absorption: The high-toughness manganese steel base effectively absorbs the massive冲击 forces from crushing hard rocks, preventing premature failure and protecting the crusher body.

- Excellent Wear Resistance: Through the work-hardening phenomenon, the surface of the cheek plate hardens under repeated impact, while the core remains tough. Our composite version takes this a step further with its inlaid wear-resistant elements.

- Stable Chamber Design: Precise casting ensures the plates maintain the correct crusher chamber geometry, promoting optimal crushing efficiency and consistent product output.

- Reduced Downtime: Manufactured with consistency and durability in mind, our cheek plates offer extended service intervals, minimizing maintenance downtime and lowering your cost per ton crushed.

Applications

Huasheng cheek plates are designed for a wide range of applications across various industries, including:

- Mining: Primary crushing of ores (gold, iron, copper, etc.) and hard rock.

- Aggregate Production: Processing of granite, basalt, quartzite, and other abrasive aggregates in quarries.

- Construction & Demolition Waste Recycling: Crushing of concrete, rubble, and other recycled materials, often with high abrasiveness.

- Infrastructure Construction: Processing raw materials for road building and other large-scale projects.

Our Commitment & Customization

With extensive on-site application experience, we understand that every operation has unique challenges. We don’t just sell products; we provide solutions. Huasheng offers personalized, cost-effective cheek plate designs tailored to your specific crusher model, feed material, and operational conditions. Our goal is to provide you with the highest value solution that maximizes your productivity and profitability.