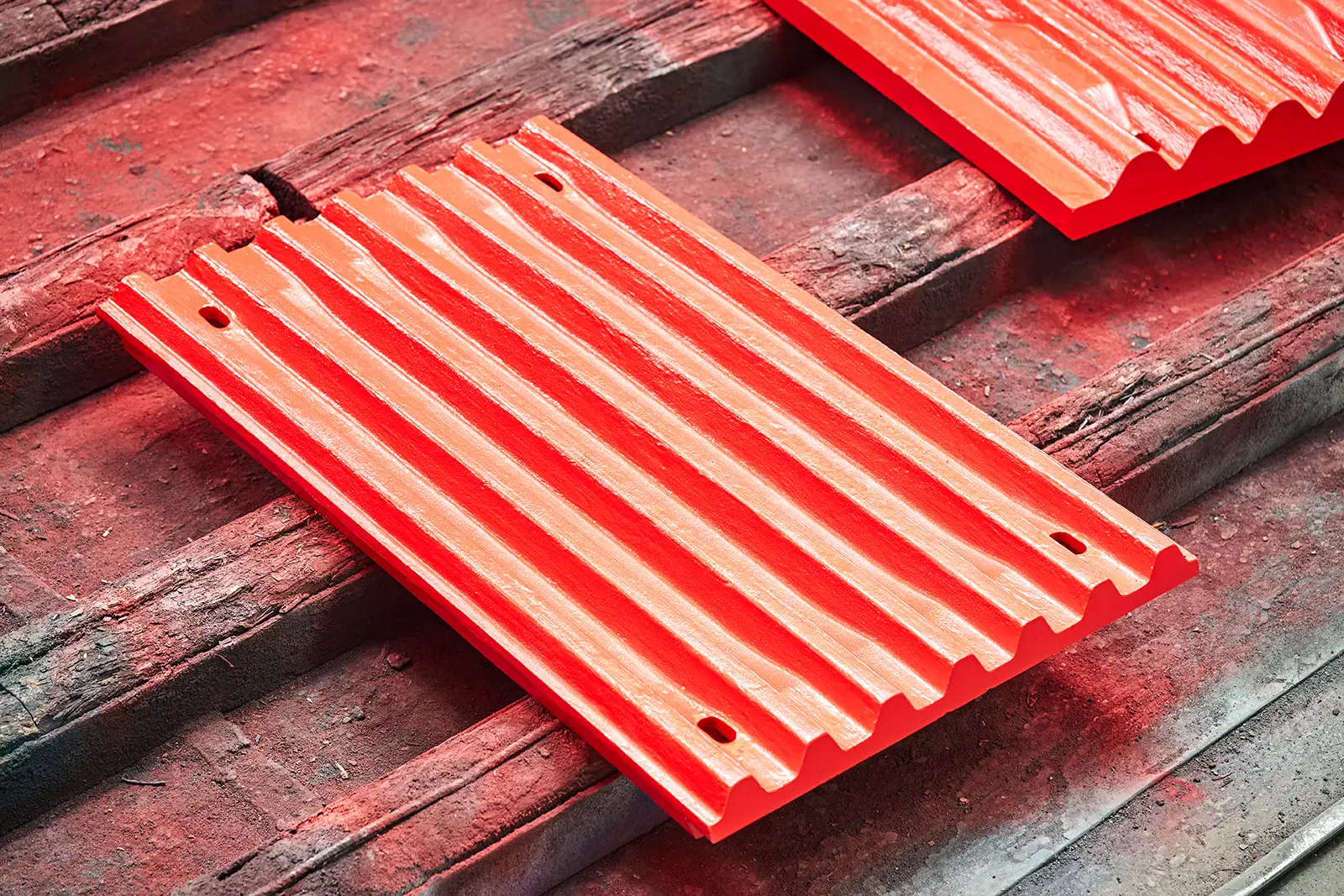

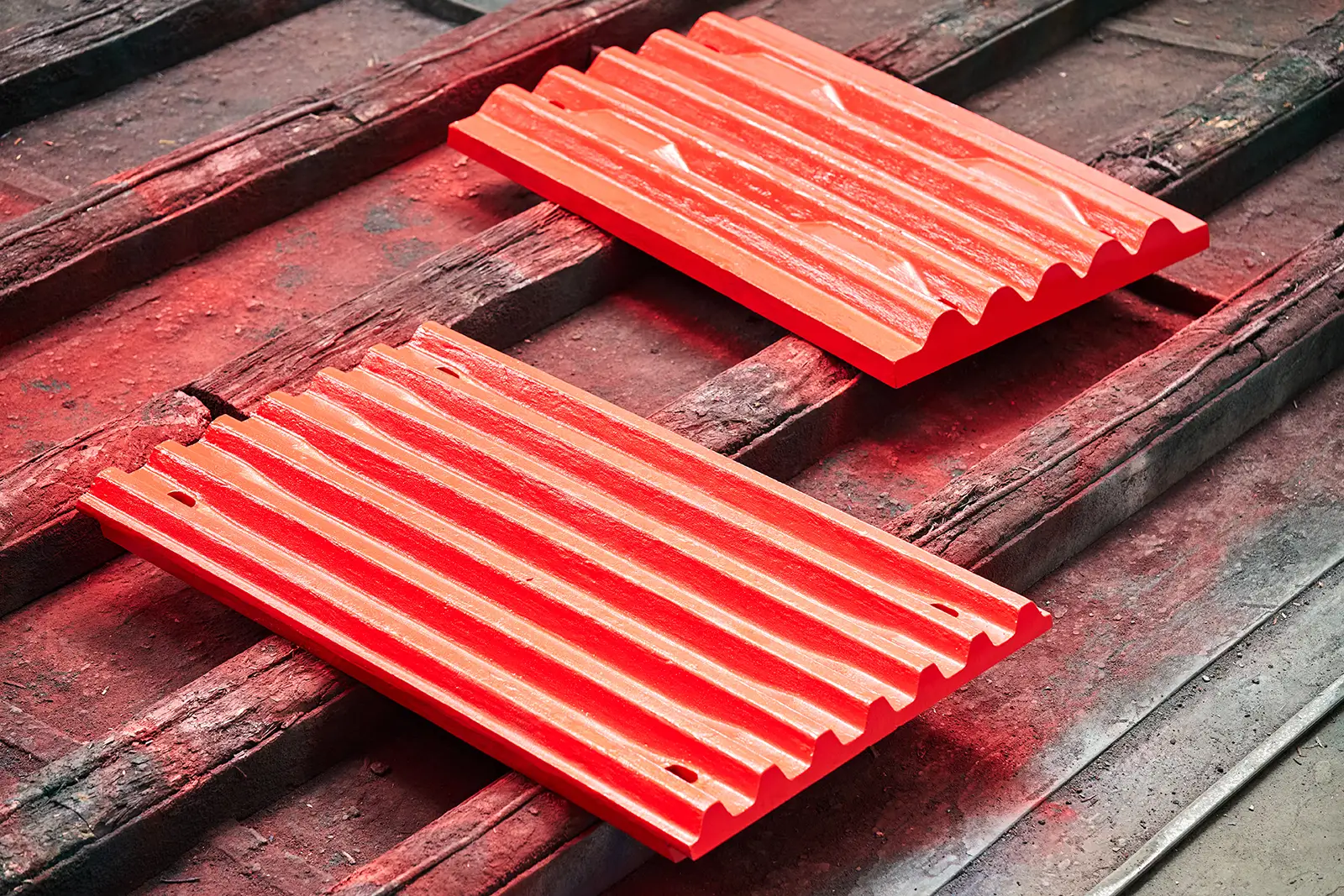

Premium Jaw Crusher Jaw Plate: Designed for Tough Tasks

Jaw Crusher Jaw Plate are essential components in primary crushing equipment, widely used in industries like mining, construction, and building materials. Huasheng, a trusted wear parts manufacturer, offers cutting-edge solutions for these demanding applications, catering to mobile crushing stations and a variety of industry-specific needs. This product lineup ensures high durability and efficiency even under the harshest working conditions, positioning Huasheng as a leading global provider of wear-resistant solutions.

Whether you are working with high-hardness materials like granite and basalt or handling the rigorous on-site demands of frequent equipment start-ups and shutdowns, Huasheng Jaw Plates deliver superior performance. With a commitment to quality and customized service, these plates are engineered to optimize the lifespan and efficiency of your crushing system.

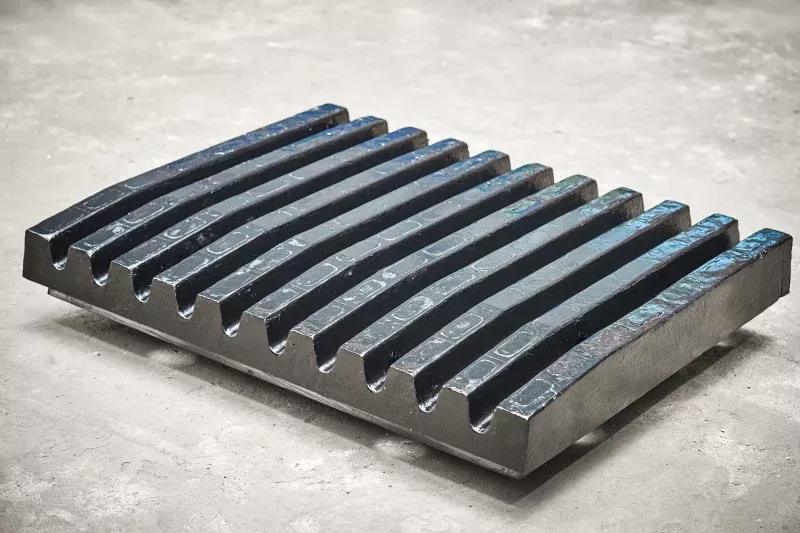

Advanced Materials for Maximum Performance

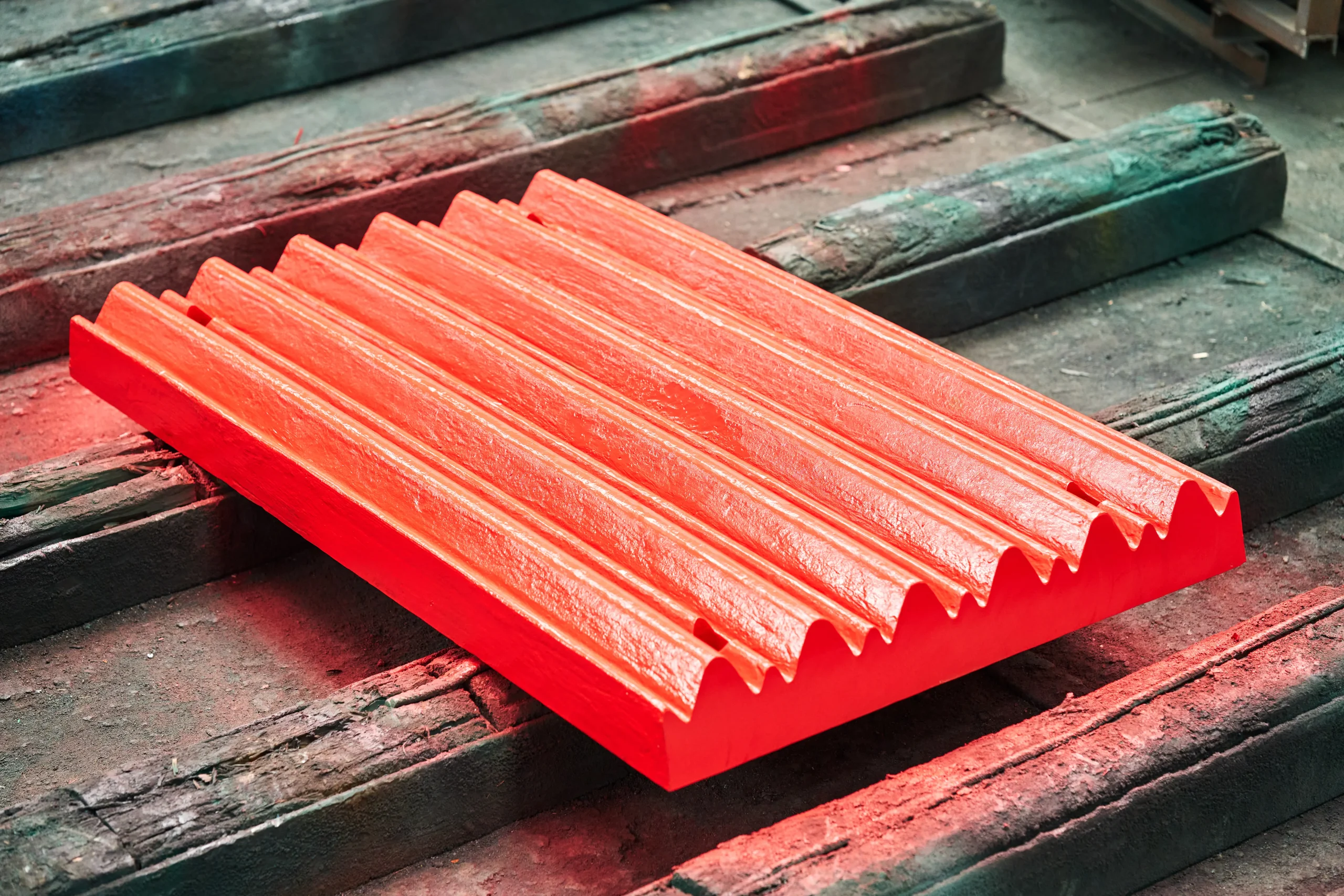

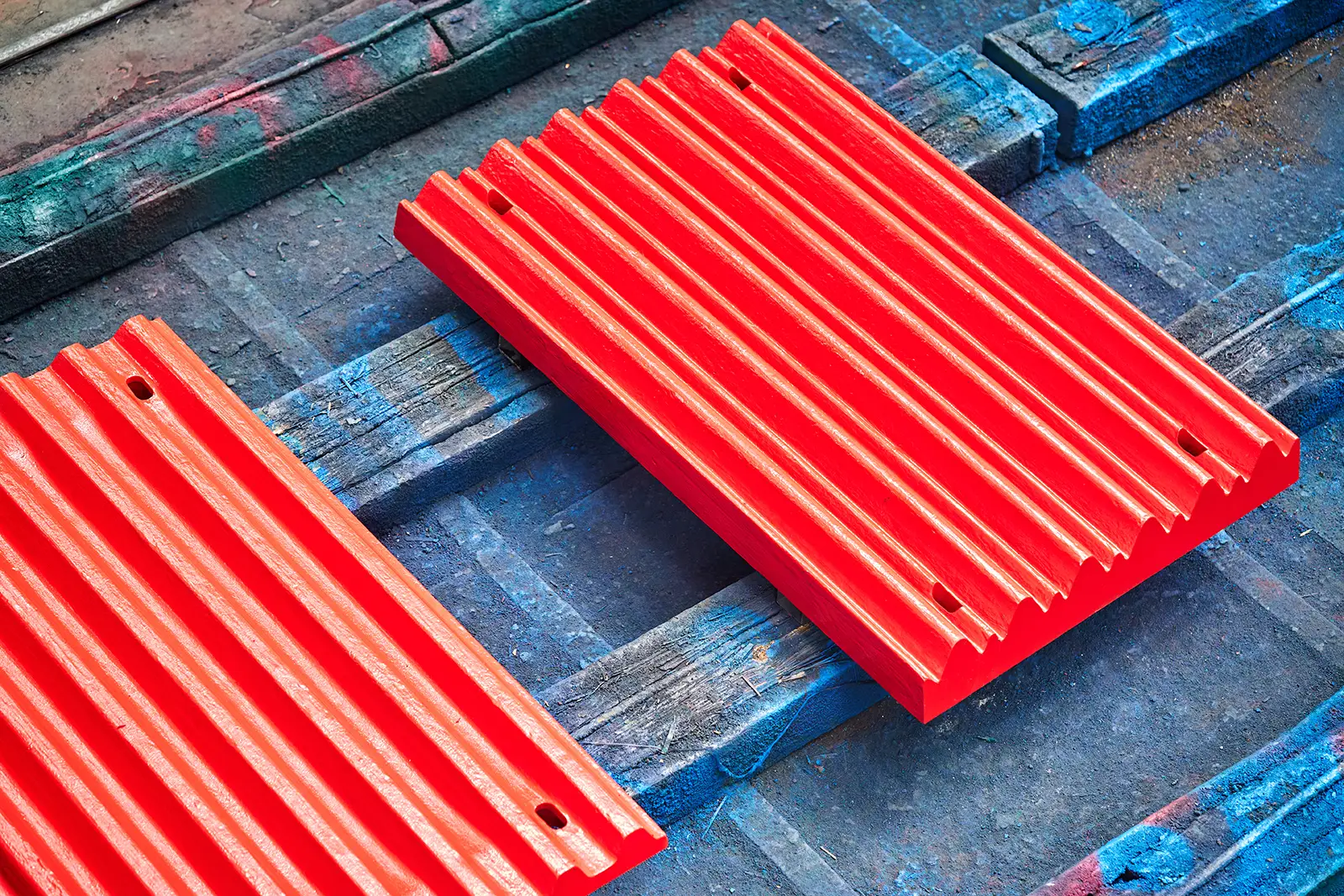

Huasheng’s Jaw Plate are crafted from industry-leading materials such as ZG Mn13Gr2, ZG Mn18Gr2, and ZG Mn22Gr2, ensuring unmatched wear resistance and toughness. These manganese steel variations are time-tested to withstand the impact and abrasion of daily operations. For specialized needs, Huasheng offers composite materials with high manganese steel bases, inlaid with titanium carbide alloy rods, ceramic modules, or high-chromium alloy blocks.

Such innovations bring unparalleled safety, reliability, and adaptability to diverse working environments. Additionally, Huasheng’s expertise in material engineering has enabled the development of high-impact resistant tooth plates, specifically tailored for primary crushing of hard rock materials. This results in an efficient, cost-effective, and robust solution capable of addressing modern industry challenges.

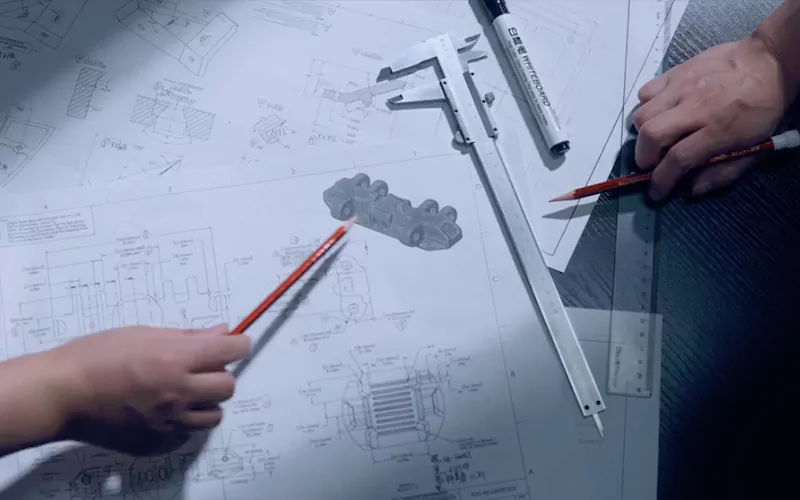

Customized Solutions for Unique Challenges

Every mining and construction project is unique, requiring tailored solutions to meet specific operational demands. Huasheng excels in providing personalized customization for Jaw Plate, offering the best cost-performance results for any working condition. With years of on-site application experience, Huasheng ensures that your equipment achieves optimal crushing effectiveness, minimizing downtime and maximizing productivity.

Designed with the aim of addressing critical challenges like severe wear from high-hardness materials or frequent mobile crushing station movement, these jaw plates deliver reliability under challenging conditions. They are the perfect partnership of durability and innovation, continuously evolving to meet industry-changing demands.

Choose Huasheng Jaw Crusher Jaw Plates to secure hassle-free operation, boosted performance, and long-term cost savings in your crushing operations. Experience the strength and efficiency that industry leaders trust.