1. Jaw Crusher Plate Key Features & Technological Advantages

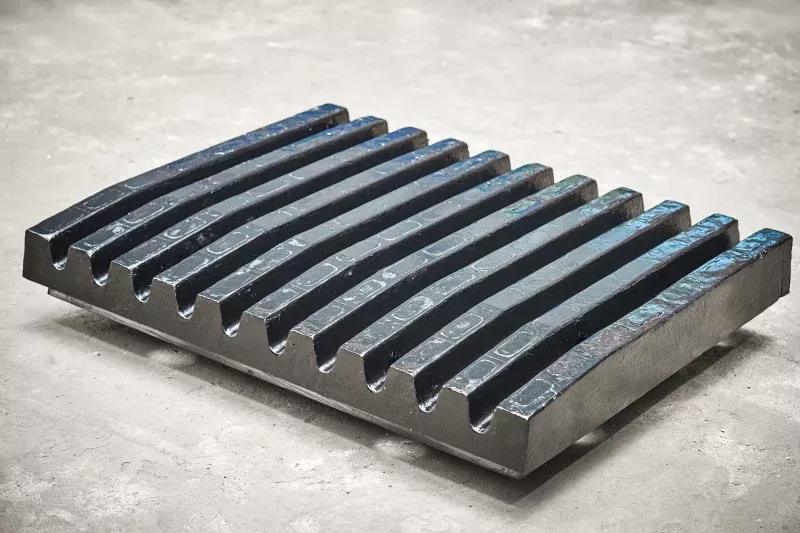

- Revolutionary Composite Structure: This product is manufactured using a proprietary process that inlays ultra-hard wear-resistant alloy bars (typically Titanium Carbide – TiC or similar super-hard alloys) directly into a high-toughness base material, such as high manganese steel (e.g., ZG Mn13Cr2, ZG Mn18Cr2). This creates a perfect synergy where the tough matrix absorbs impact energy, and the hard alloy bars resist cutting and abrasion.

- Exceptional Wear Resistance & Longevity: The primary advantage is a dramatic increase in service life. The inlaid alloy bars form a permanent, ultra-wear-resistant surface that protects the underlying matrix from direct abrasion. This can extend operational life by multiple times compared to standard homogeneous plates, drastically reducing replacement frequency and downtime.

- Superior Impact Absorption: Unlike brittle materials that offer high hardness but low impact resistance, our design utilizes a high-manganese steel or other tough alloy as the base. This ensures the plate can withstand the high-impact shocks and fluctuating loads inherent in crushing hard, feed material without cracking or failing.

- Optimized Cost-Efficiency: While the initial investment is higher, the significantly extended service life results in a substantially lower cost per ton of material crushed. This translates into major long-term savings on parts inventory, maintenance labor, and machine downtime, offering an excellent return on investment.

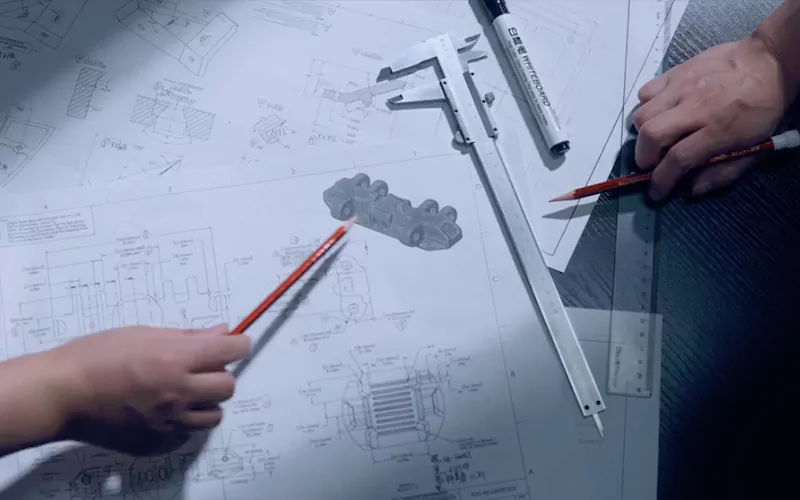

- Full Customization & Engineering Support: As a foundry with extensive application experience, we provide complete customization. We tailor the pattern, density, size, and type of inlaid alloy bars, as well as the base material composition, to your specific crusher model, feed material characteristics (e.g., granite, basalt, iron ore), and operational goals for optimal performance and value.

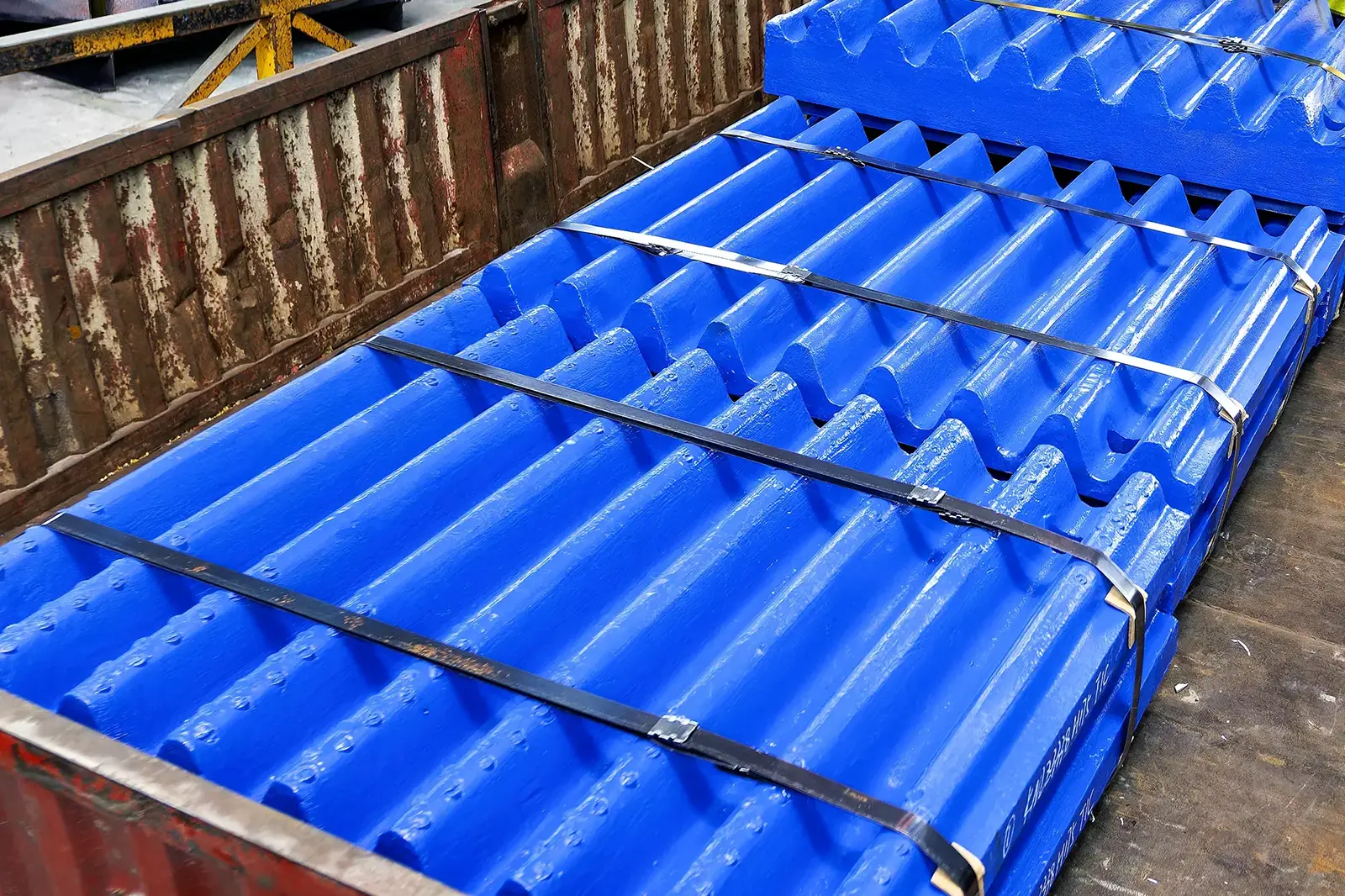

- Inlaid Wear-Resistant Alloy Bar And Jaw Crusher Plate

2. Jaw Crusher Plate Application Scope

Our Inlaid Wear-Resistant Alloy Bar Jaw Crusher Plates are the ideal solution for the most demanding crushing applications involving highly abrasive and/or hard materials, including:

- Highly abrasive granite, quartzite, and basalt

- Abrasive iron ore, copper ore, and gold ore

- Recycled materials with high abrasive content (e.g., concrete, asphalt)

They are suitable for all major models of jaw crushers in primary and secondary crushing stages where maximum wear life is critical.

3. Our Manufacturing Capability & Commitment

Huasheng is a trusted manufacturer specializing in wear parts for crushing equipment.

- Material Expertise: We master a wide range of materials, from standard grades like ZG Mn13Cr2 to advanced composites. Our specialty lies in manufacturing plates with a high-manganese steel base embedded with titanium carbide alloy bars and high-chromium alloy blocks.

- Proven Performance: Our solutions are backed by rich field experience across diverse and challenging operating conditions globally, ensuring we provide reliable and effective products.

- Quality Assurance: Every jaw plate is produced under stringent quality control measures, guaranteeing superior metallurgical properties, precise dimensional accuracy, and consistent performance.

For unparalleled wear life and reliability in the most abrasive crushing environments, choose Huasheng’s Inlaid Wear-Resistant Alloy Bar Jaw Crusher Plate. Contact our engineering team today to customize a high-performance, cost-effective wear solution that will maximize the productivity of your crushing operation.