Understanding Impact Plates in Impact Crusher Wear Parts

What Are Impact Plates?

Impact plates are essential components in the realm of impact crushers. Designed to absorb the shock of falling materials, these robust plates help in the efficient yet safe processing of heavy materials. They play a critical role in determining the performance and durability of the impact crusher itself.

The Importance of Quality Impact Plates

When considering impact crusher wear parts, the quality of impact plates cannot be overstated. High-quality impact plates enhance the lifespan of your equipment, reduce maintenance costs, and ensure that your operations run smoothly. Found in various designs and compositions, these wear parts should be chosen based on the specific type of material you are crushing.

Choosing the Right Manufacturer for Impact Plates

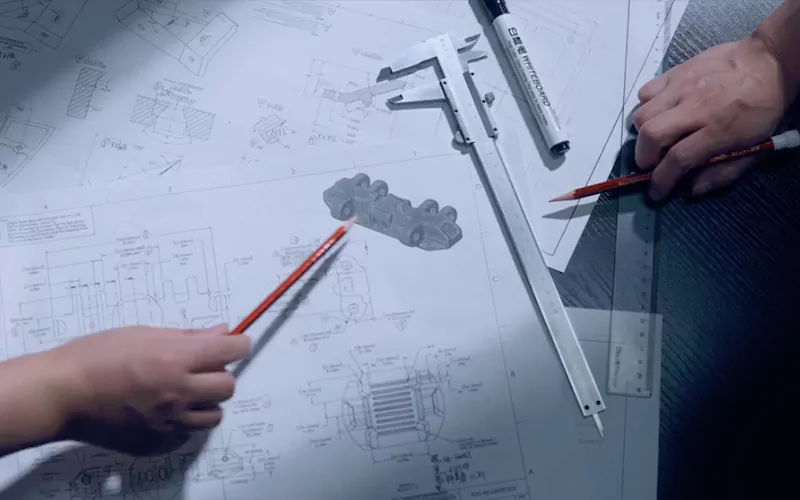

At Huasheng Castings, we pride ourselves on being your custom factory for impact plates. Our extensive experience ensures that you receive tailored solutions that meet your unique requirements. From original designs to replacements, our impact crusher wear parts are manufactured with precision and care, promising optimal performance in your operations.

Investing in quality impact plates can significantly affect your productivity. Let Huasheng Castings be your trusted partner in achieving exceptional results with your impact crusher.