Maximize Efficiency with Huasheng’s Metal Shredder Accessories

Huasheng is revolutionizing the metal recycling industry with its superior range of shredder accessories tailored for crushing waste materials. Designed for high-impact and high-tear applications, these accessories excel in processing scrapped vehicles, mixed scrap steel, and non-ferrous metals, making them indispensable for waste metal recycling operations. With a commitment to quality and performance, Huasheng’s products ensure durability, energy efficiency, and exceptional results in a variety of applications.

Premium Materials for Long-Lasting Performance

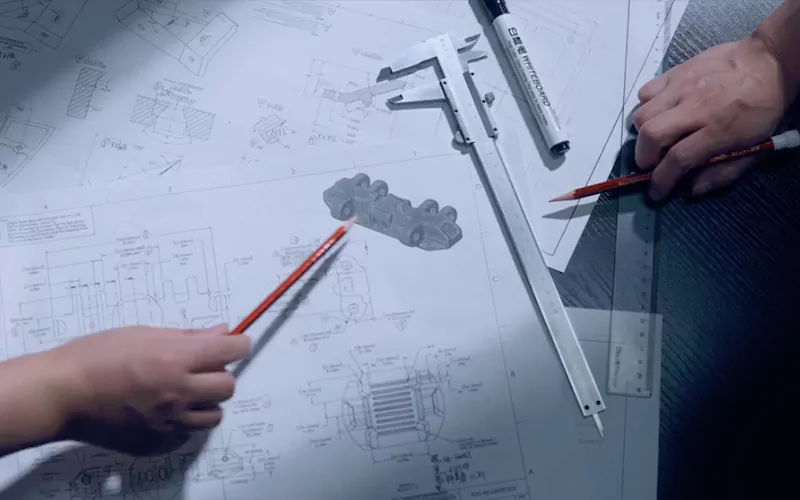

Huasheng’s shredder accessories are manufactured using robust materials such as ZG Mn13GrMo, ZG Mn13, and dual-hardness alloy steel. These materials are specifically engineered to withstand the demanding conditions of metal shredding. The dual-hardness alloy steel hammers are particularly effective in high-impact scenarios, offering unmatched wear resistance and reducing the risk of hammer head fractures. With rich on-site application experience, Huasheng provides solutions that are not only reliable but also tailored to the specific needs of your operations, ensuring the highest cost-performance ratio.

Advanced Design for Optimal Productivity

Huasheng integrates a gradient impact-resistant structure and innovative anti-wrapping design into its shredder accessories. This design significantly extends the average service life of hammer heads by up to 2.8 times while cutting energy consumption per ton of crushing by over 35%. With over 200 practical applications in metal recycling plants, the company’s products have demonstrated unparalleled performance, allowing operators to achieve efficient and sustainable metal recycling processes.

Personalized Solutions for Your Metal Recycling Needs

Understanding the diverse requirements of the metal shredding industry, Huasheng provides customized solutions to meet unique challenges. Whether you are dealing with scrapped vehicles, mixed scrap steel, or multi-material mixtures, Huasheng’s full range of ZG Mn13GrMo to dual-hardness composite hammerhead solutions are designed to deliver optimized efficiency and durability. Reduce downtime and improve cost-effectiveness with accessories that are meticulously crafted and customized according to your operational demands.