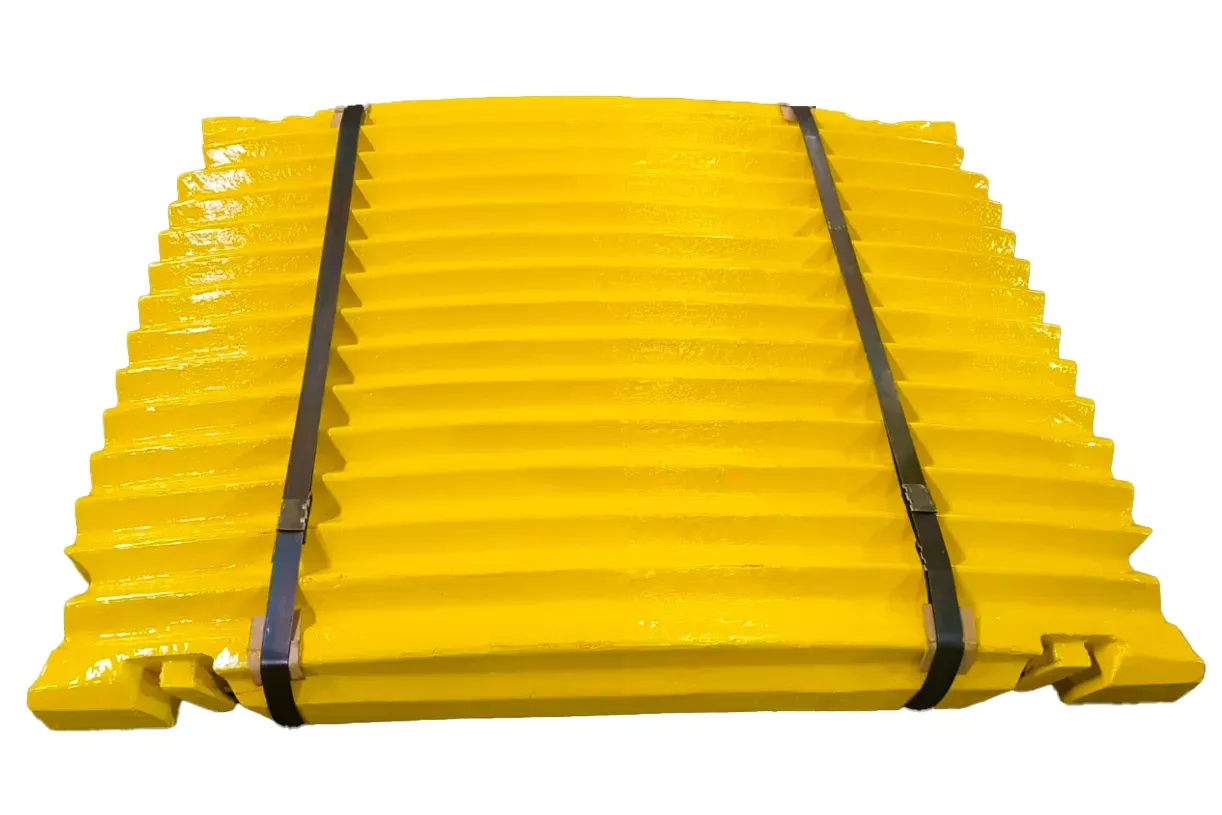

Product description

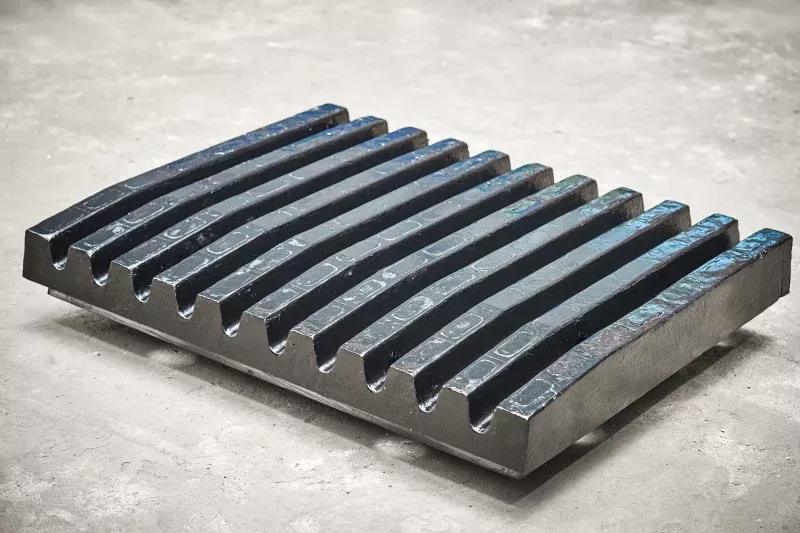

Jaw plate is manufactured with super high manganese steel, therefore it has a service life 50~100% longer than those made of traditional high manganese steel. Every model of PE series jaw crushers is tested for shock, stress, strain, thermal loading, deformation, vibration and noise under a wide range of load conditions. The special processing techniques ensure that our jaw plate has leading performance:

1)Using cold processing hardening technology, the hardness is improved.

2)Water toughening technology to avoid making the performance poor during the process of natural phase change.

We manufacture an extensive range of wear and spare parts in China for the worlds most popular crushing brands, like the spare parts for the below crushers.

1. Key Features & Technological Advantages

- Advanced Material Science: This product is manufactured from a proprietary High-Aluminum High-Manganese Steel alloy. The strategic addition of aluminum, along with standard elements like chromium (Cr), significantly enhances the material’s performance beyond traditional manganese steels (e.g., ZG Mn13Cr2, ZG Mn18Cr2).

- Superior Work Hardening Capability: Retaining the classic property of manganese steel, our alloy work-hardens upon impact. The continuous impact and compression during crushing operations cause the surface hardness to increase dramatically, forming a hardened layer that resists abrasion deeply, while the core remains tough to absorb high impact stresses without fracturing.

- Enhanced Yield Strength and Durability: The high aluminum content notably increases the yield strength and overall durability of the tooth plate. This results in significantly higher resistance to deformation and failure under heavy load conditions, ensuring the plate maintains its optimal shape and geometry for longer, which promotes crushing efficiency and consistent product size.

- Improved Wear Resistance & Service Life: The synergistic effect of aluminum and manganese creates a microstructure that offers exceptional resistance to abrasion and gouging. This translates to an extended operational lifespan, reducing the frequency of replacements, lowering downtime, and offering a better cost-per-ton crushed compared to standard alternatives.

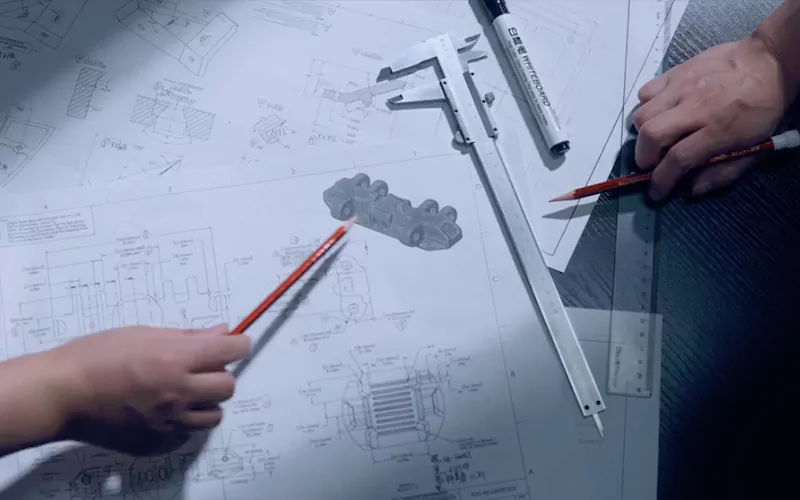

- Customization and Precision Manufacturing: As a specialized foundry, Huasheng provides full customization. We engineer each toothed plate to your crusher model and specific application needs. This includes custom tooth profiles, dimensions, and alloy optimization to handle your specific feed material, ensuring maximum productivity and value.

- Jaw Crusher Wear Parts Factory

2. Application Scope

Our High-Aluminum High-Manganese Steel Toothed Plates are ideally suited for processing tough and abrasive materials where high impact is also a major factor, including:

- Hard and abrasive granite, basalt, and quartzite

- Iron ore and other metal ores

- Demolition concrete and recycled construction materials

They are compatible with all major jaw crusher models and are particularly effective in high-impact primary crushing stages.

3. Our Manufacturing Capability & Commitment

Huasheng is a trusted manufacturer of wear parts like jaw plates and accessories. Our expertise extends beyond standard materials like ZG Mn13Cr2 and ZG Mn18Cr2 to advanced alloys and composites.

- Material Versatility: We offer a range of materials and also specialize in composite solutions, such as a high-manganese steel base embedded with titanium carbide (TiC) rods and high-chromium alloy blocks for extreme applications.

- Engineering Support: Leveraging our extensive field experience, we provide personalized, cost-effective solutions tailored to deliver the highest value and performance for your specific operating conditions.

- Quality Assurance: Every tooth plate is produced under strict quality control protocols to ensure metallurgical integrity, dimensional accuracy, and performance reliability.

For a robust, impact-resistant, and long-lasting solution for your jaw crusher, choose Huasheng High-Aluminum High-Manganese Steel Toothed Plates. Contact our engineering team to discuss a customized solution that will optimize your crushing operation’s efficiency and profitability.