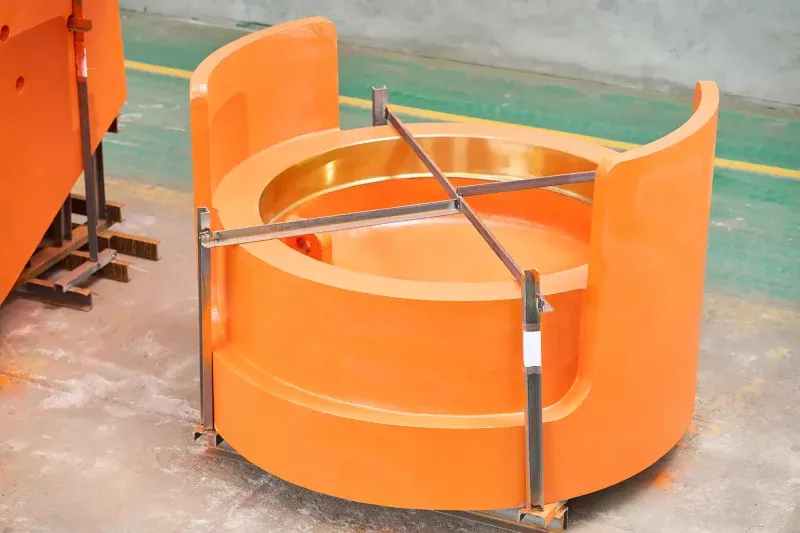

Gyratory Crusher Concave Wear Parts The gyratory crusher is a heavy-duty crushing machine widely used in the mining and aggregate industries, characterized by high output, strong adaptability, and low crushing costs. HuaSheng is a manufacturer of wear parts, cone components, and other accessories for this equipment, offering a diverse range of material options for wear parts, including high-manganese steel, high-chromium alloy, chromium-molybdenum alloy steel, and composite liners, among others. With extensive on-site application experience, HuaSheng provides customized solutions that offer the highest cost-effectiveness.