Shredder hammers are pivotal to operational efficiency in metal recycling plants. As scrap composition evolves – becoming lighter with increased plastics and softer materials – traditional manganese steel hammers often fail to achieve adequate work hardening, reducing their effectiveness and lifespan.

Engineered for the Modern Scrap Challenge:

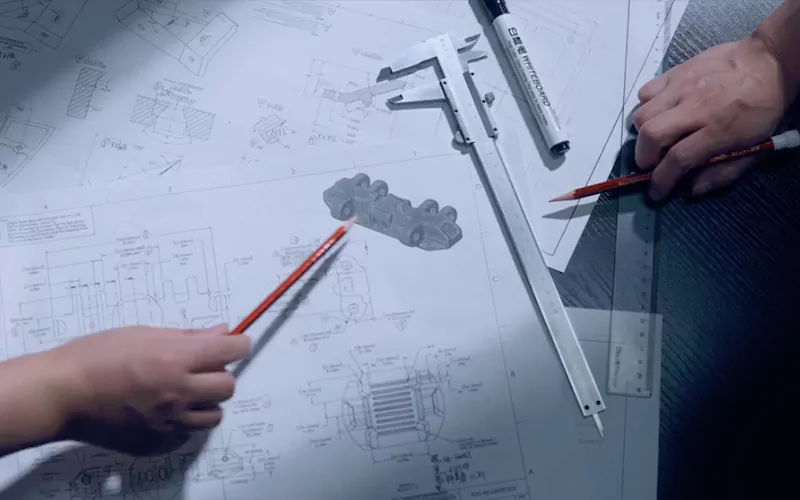

Huasheng Castings, a leading precision foundry specializing in metal crusher wear parts, developed the Dual Hardness Alloy Steel Hammer specifically to overcome these limitations. Our solution delivers significantly extended service life and enhanced economic performance for all shredder types.

Superior Design & Material Science:

Dual Hardness Technology: A special alloy formulation creates a hammer that is exceptionally hard in critical impact zones, while maintaining necessary toughness in the core. This unique property combats wear aggressively where it matters most.

Optimized Geometry Retention: The hardened zones resist deformation far better than manganese steel, preserving the hammer’s original profile and crucial “sweet spot” for longer. This ensures consistent material grab, optimal feed into the shredder box, and sustained high production rates throughout the hammer’s operational life.

Enhanced Performance: The alloy’s higher yield point allows for the design and use of thicker, more robust hammers without rotor jamming risks. This translates into greater striking force, improved material breakage, and superior non-ferrous metal liberation and recovery.

Huasheng Manufacturing & Quality Assurance:

As your dedicated casting partner, Huasheng Castings leverages advanced foundry capabilities to deliver:

Stable, High-Performance Castings: Rigorous process control ensures consistent metallurgy and optimal properties in every batch.

Mass Production & Customization Expertise: We excel at both high-volume output and tailored solutions to meet specific shredder rotor and material requirements.

Comprehensive Quality Control: Every single Dual Hardness Alloy Steel Hammer undergoes rigorous inspection, including:

Magnetic Particle Inspection (MT): Detects surface and near-surface flaws.

Precision Hardness Testing: Verifies dual hardness specifications are met.

Dimensional Verification: Ensures exact fit and function for your rotor.

Upgrade Your Shredding Efficiency Today.

Choose Huasheng Dual Hardness Alloy Steel Hammers – engineered for maximum durability, productivity, and cost savings in demanding recycling environments.