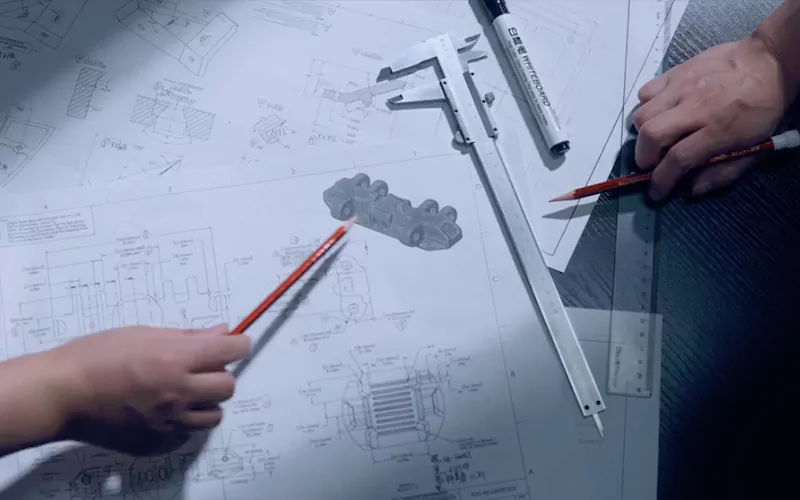

As a manufacturer specializing in mining crushing wear parts for 14 years, Huasheng provides customized solutions that are wear-resistant and cost-effective for global cone crusher users. For materials such as iron ore, granite, and river pebbles in secondary/tertiary crushing applications characterized by high abrasion and moderate to high impact conditions, we integrate the full range of high-manganese steel substrates from ZG Mn13Cr2 to Mn22Cr2 with composite reinforcement technology. Through over 300 field case studies, we have validated an average extension of liner lifespan by 40-200%, helping to reduce crushing costs per ton by over 25%.