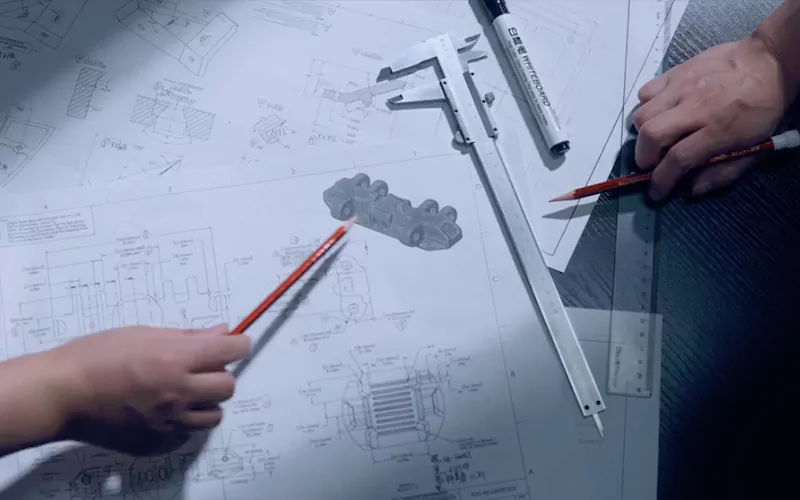

Mining Shovel Crawler Shoes

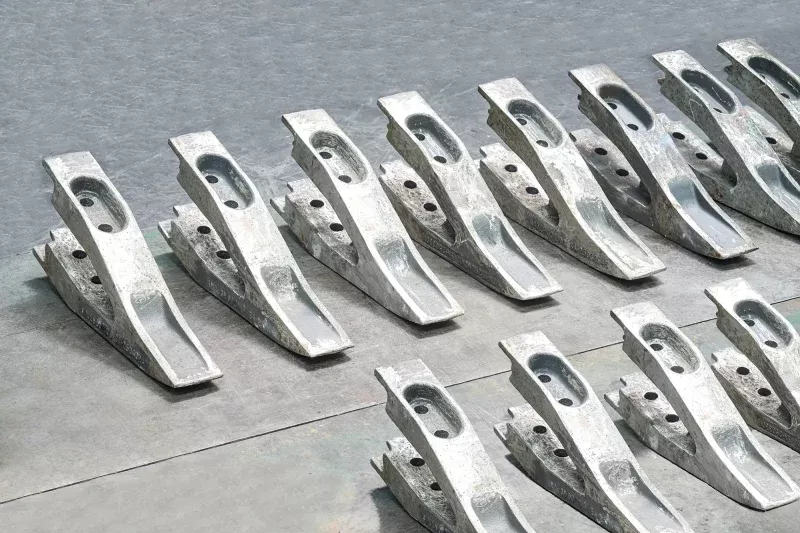

As a premier manufacturer of heavy-duty undercarriage systems for 200+ ton mining shovels, Huasheng has delivered over 200,000 sets of high-manganese steel crawler shoes to global mining operations. Our engineered solutions target critical wear points in harsh mining environments, reducing maintenance downtime by 25-40% through:

✓ Material Science Leadership: Proprietary Hadfield Steel (Mn11-14%) & Cr-Mo Alloy Steel

✓ Advanced Casting Techniques: Vacuum Degassing + Controlled Solidification

✓ Heat Treatment Innovation: Deep Case Hardening (8-12mm depth)

Our technological edge lies in wear-zone specific engineering:

Optimized Contact Geometry: 22% larger ground engagement area vs. industry standard

Patented Hardening Process:

For Manganese Steel: Water Quenching & Tempering achieving metastable austenite structure

For Alloy Steel: Deep Induction Hardening (Case depth: 8-12mm, Surface hardness: 550-600 HB)

Interpart Wear Control: Chamfered edges prevent adjacent component damage

By analyzing site-specific conditions (abrasiveness, impact levels, tramming distance), we deliver custom-cast crawler systems that outperform OEM standards:

✓ 30% Longer Wear Life in high-silica copper mines

✓ Interchangeability Guarantee: Compatible with P&H 4100XPC, Bucyrus 495HR, CAT 7495

✓ Rapid Deployment: 15-30 days lead time for critical replacements

Material Range: ASTM A128 Gr.B2/B3, DIN GX120Mn12, JIS SCM440

Process Control:

▸ Chemical composition tolerance: ±0.15%

▸ Non-destructive testing: UT/MT 100% coverageCustomization: Bolt-hole patterns, grouser height (50-120mm), width adaption