Jaw Crusher Parts

Jaw Crusher Parts

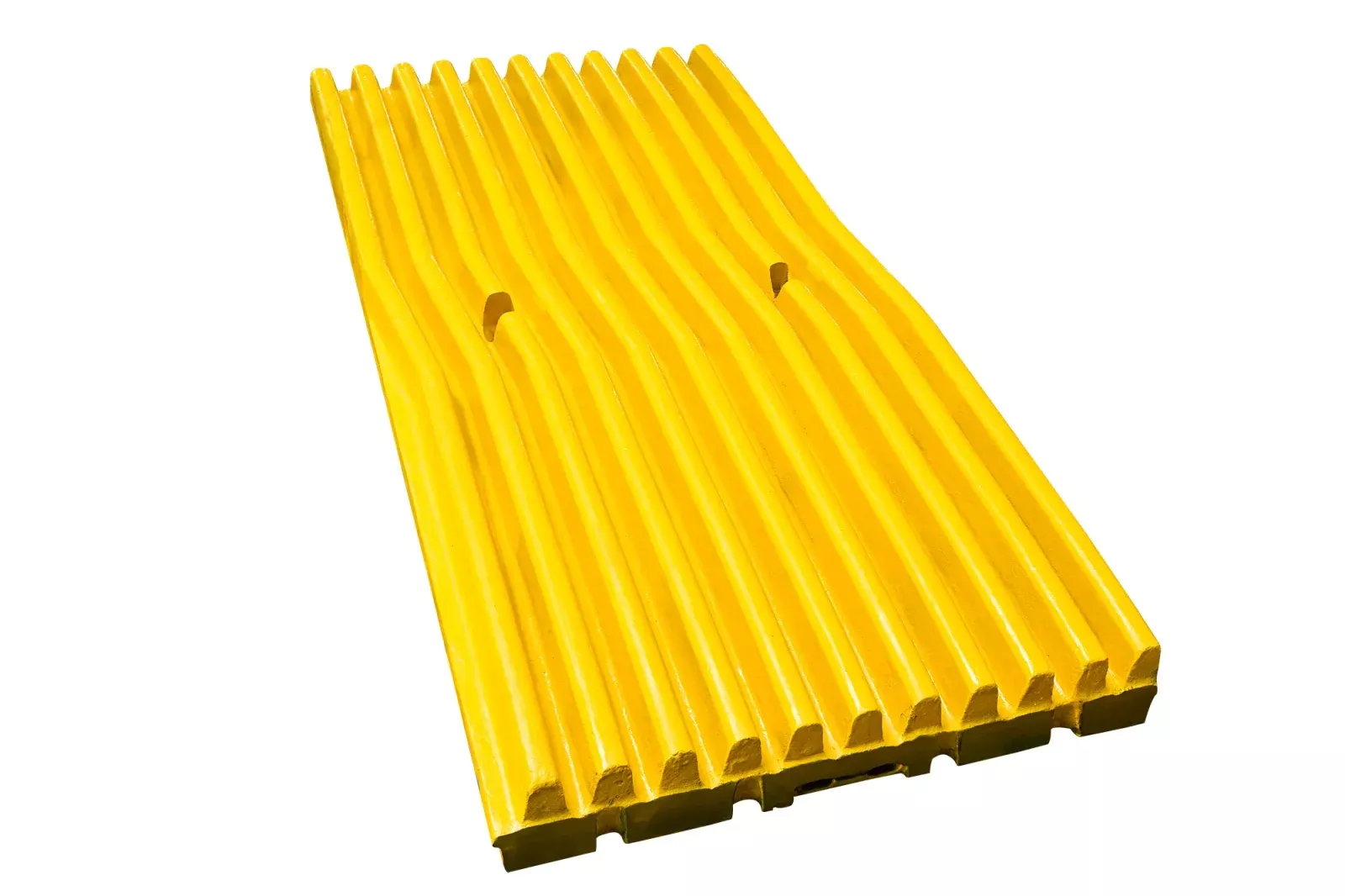

Jaw crushers are a common primary crushing equipment and the first choice for coarse crushing in mobile crushing, widely used in industries such as mining, building materials, and infrastructure construction. Huasheng is a manufacturer of Jaw Crusher Parts like tooth plates and other accessories for this equipment. The main materials include standard materials such as ZG Mn13Gr2, ZG Mn18Gr2, and ZG Mn22Gr2, and it has rich on-site application experience, enabling it to provide personalized customization with the highest cost-performance solutions. It can also provide composite materials with high manganese steel as the base material, inlaid with titanium carbide alloy rods, ceramic modules, and high-chromium alloy blocks.

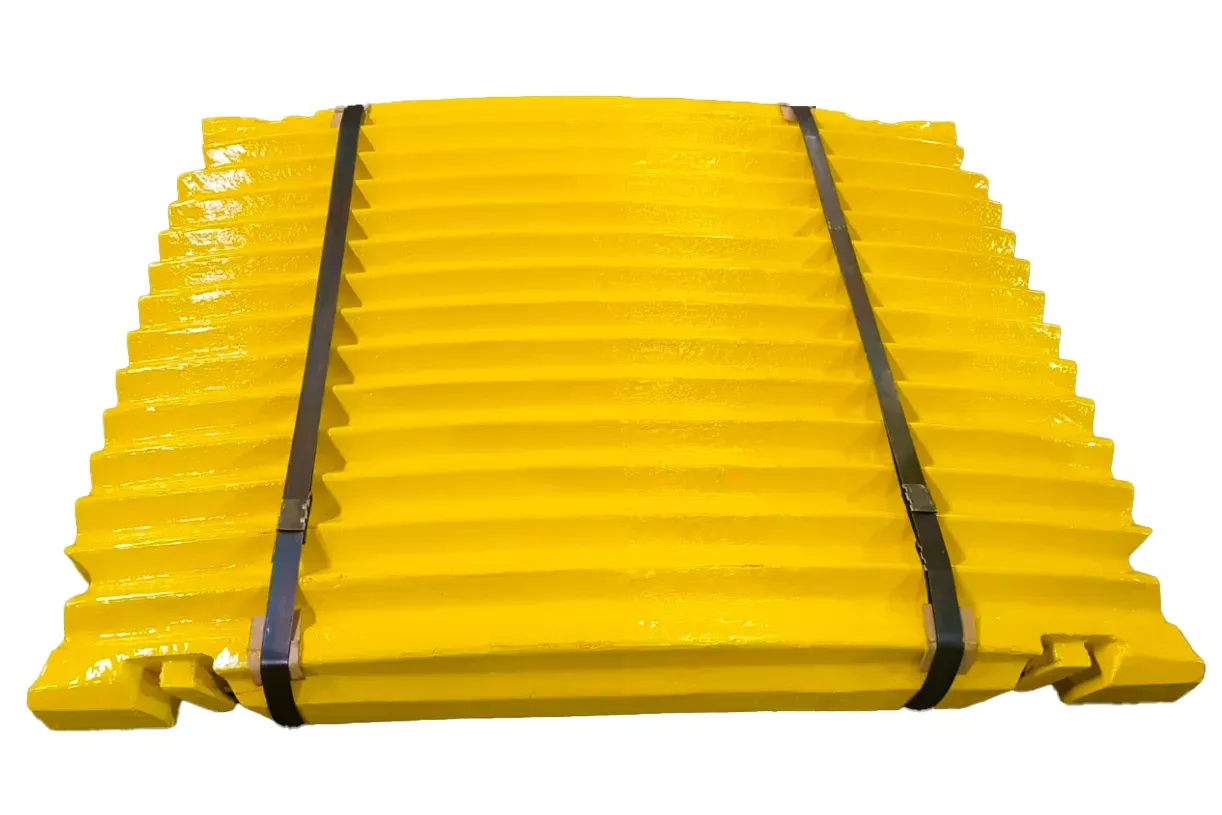

As a global wear-resistant solution partner in the fields of mining and construction waste recycling, Huasheng has specially developed high impact-resistant tooth plates for the primary crushing conditions of jaw crushers. Addressing the severe challenges posed by high-hardness materials such as granite and basalt, as well as the frequent start-ups and shutdowns of mobile crushing stations, we can provide personalized product services based on different working conditions.

Inquiry

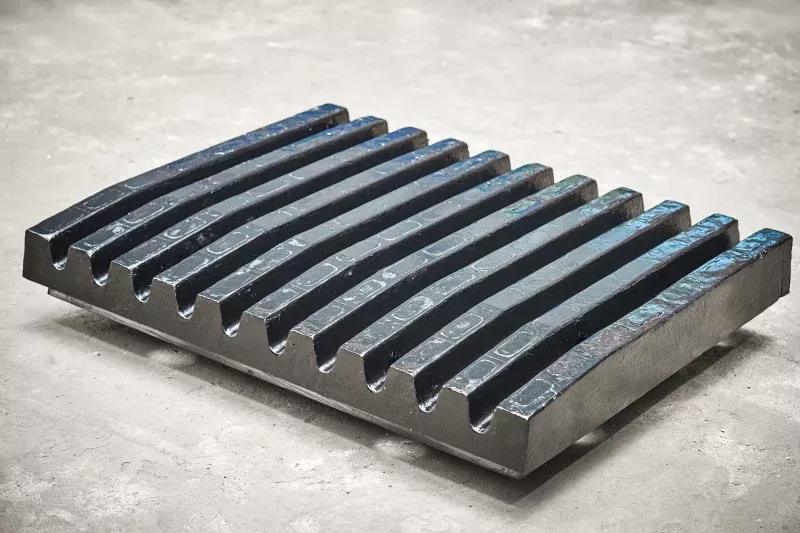

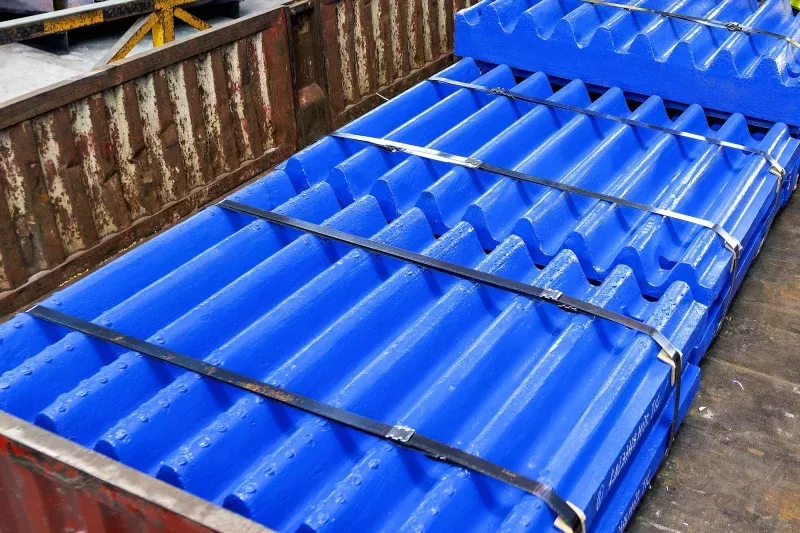

Jaw Crusher Parts Products

The most used ingredients in the current market are listed below:

| Model Number | C | Mn | Si | P | S | Cr |

| ZG120Mn13Cr2 | 1.05-1.35 | 11.0-14.0 | 0.3-0.9 | ≤0.06 | ≤0.04 | 1.5-2.5 |

| ZG120Mn18Cr2 | 1.05-1.35 | 16.0-19.0 | 0.3-0.9 | ≤0.06 | ≤0.04 | 1.5-2.5 |

| ZG120Mn21Cr2 | 1.05-1.35 | 19.5-23.5 | 0.3-0.9 | ≤0.06 | ≤0.04 | 1.5-2.5 |

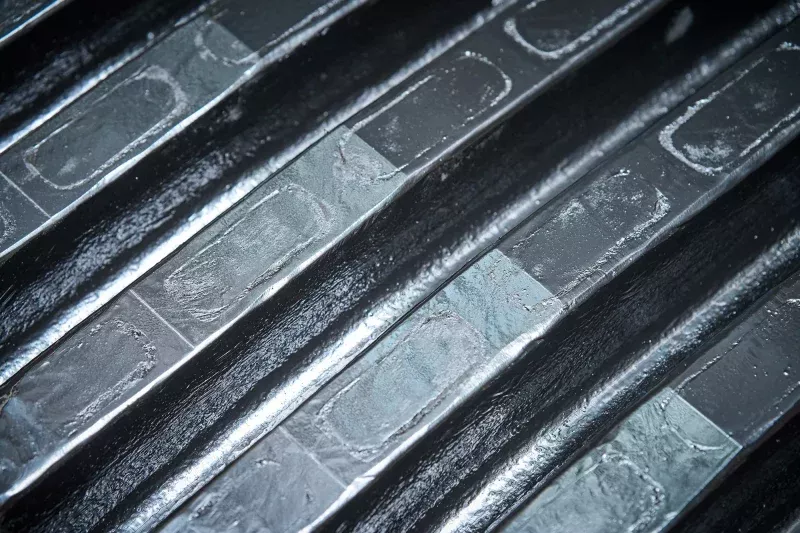

Metallographic grade requirements: GB/T 13925-2010 standard evaluation (undissolved carbide ≤ W3; precipitation carbide ≤ X3)

Grain size grade with reference to GBT6394 standard, at present our grain size grade control to 2.5-4 levels

1. Inlaid Wear-Resistant Alloy Bar And Tooth Plate Inlaid High Chrome Cast Iron Tooth Plate

2. Inlaid High Chrome Cast Iron Jaw Crusher Tooth Plates

3. High-Aluminum And High-Manganese Steel Toothed Plate

4. Different tooth shapes for different industrial and mining conditions

Advantage

Raw material control

Customized

Rich experience

Quality inspection

Process

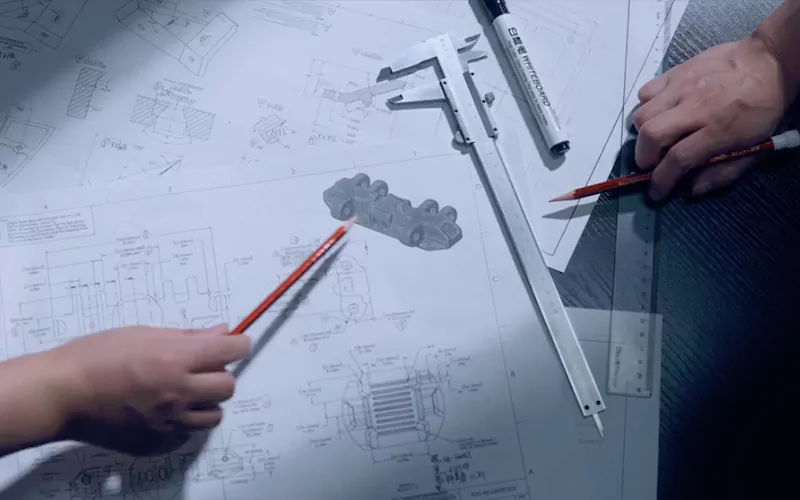

1.Process design

2.Pattern Making

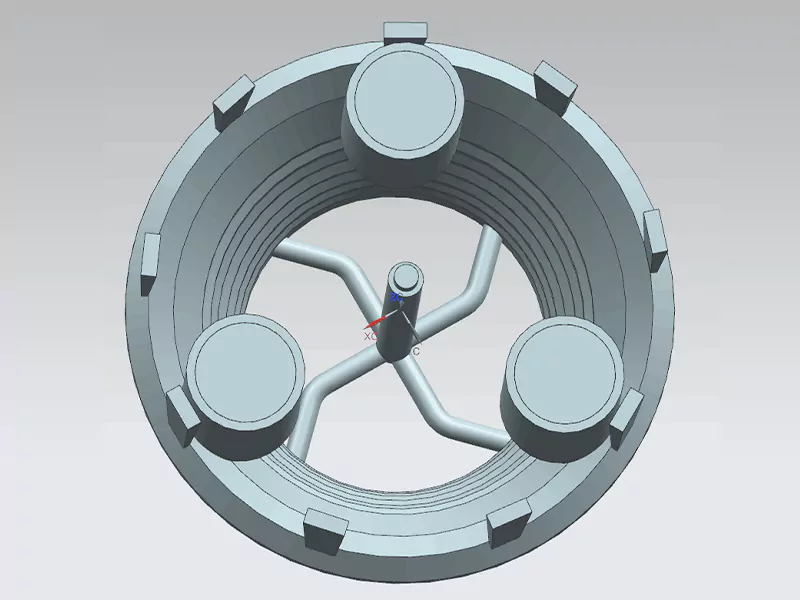

3.Modeling

4.Coating

5.Casting

6.Pouring

7.Clean

8.Heat Treatment

9.Grinding workshop

10.Machining

11.Inspection