Impact Crusher Wear Parts

Impact Crusher Wear Parts

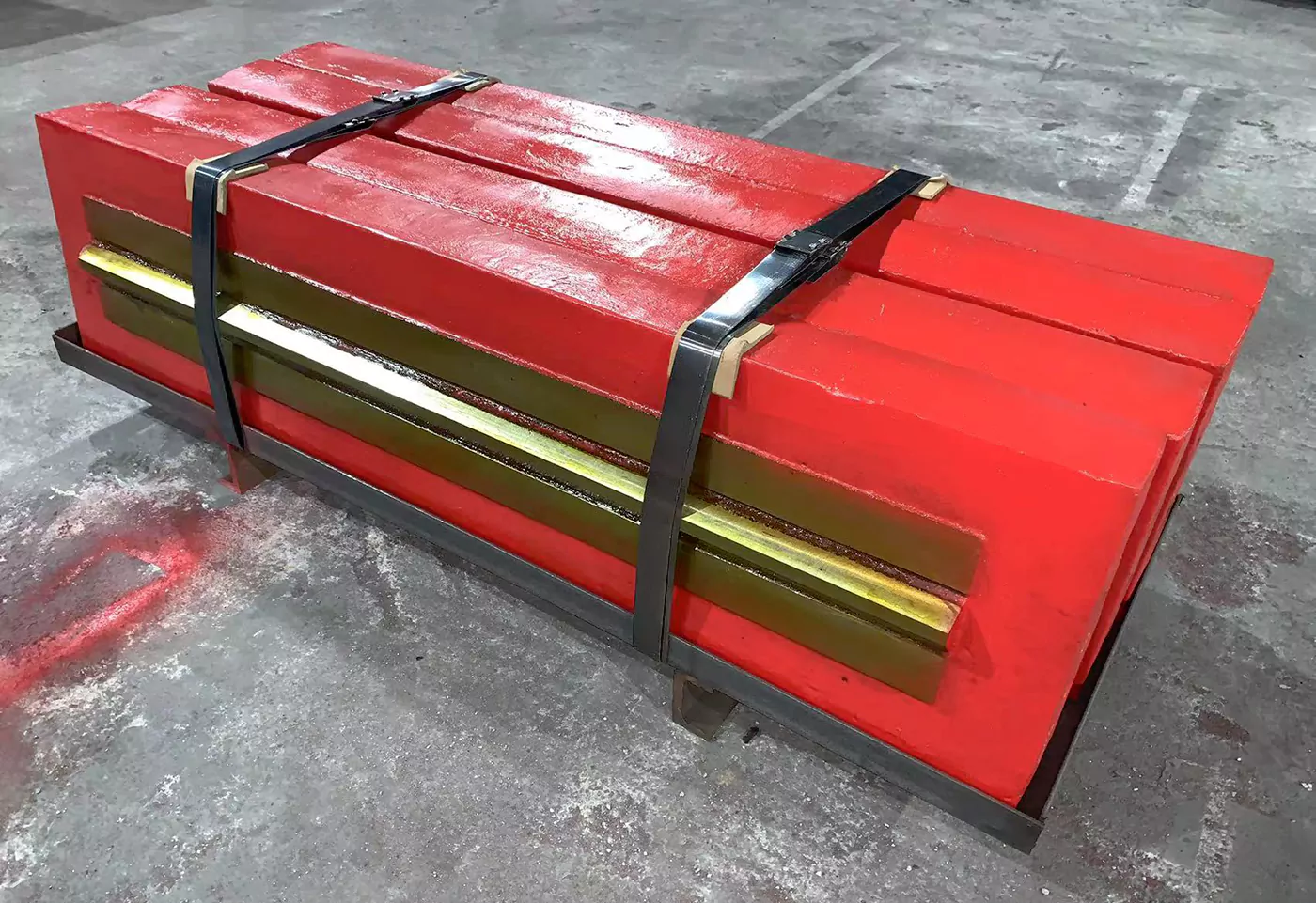

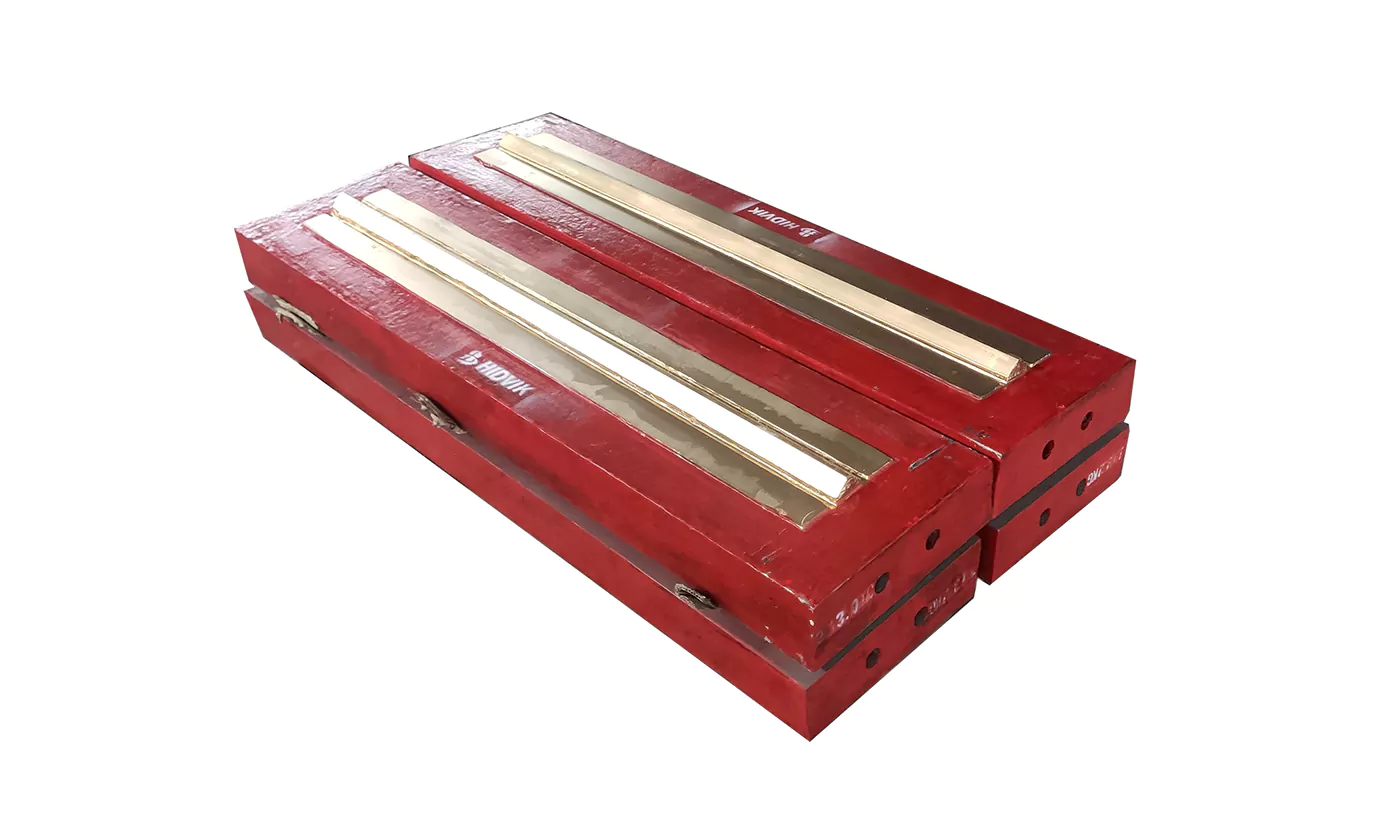

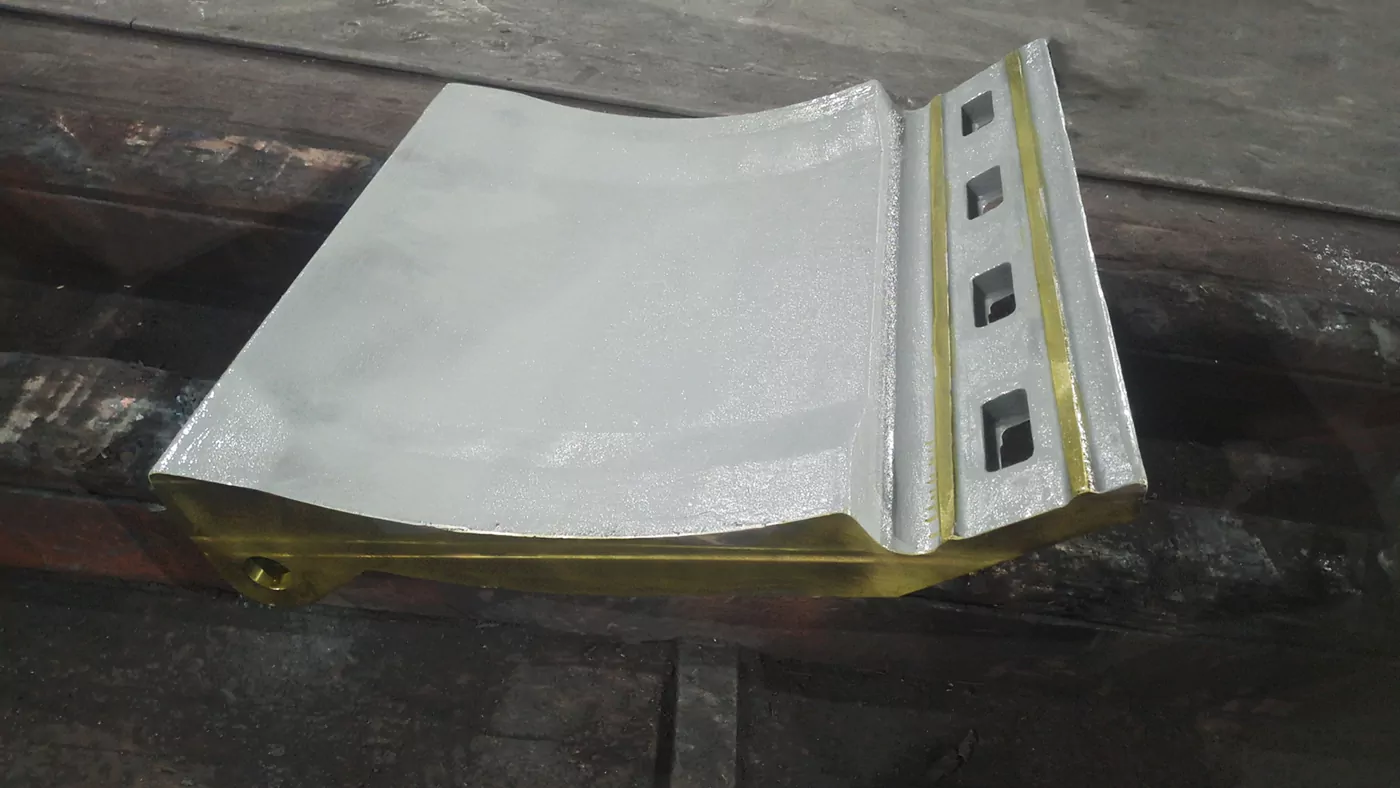

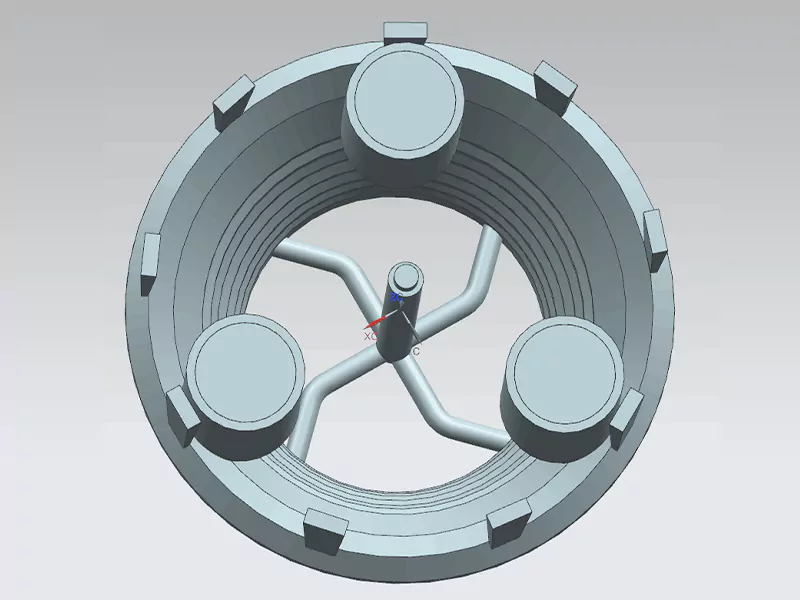

An Impact Crusher Wear Parts crusher is a crushing machine that uses impact energy to crush materials, widely used in the shaping of building stone production, crushing in the cement industry, recycling of concrete crushing, and other medium-hard and soft materials. The common materials of impact hammers include high manganese steel, martensitic steel, martensitic inlaid ceramics, high chromium cast iron, and inlaid ceramics. Huasheng is a manufacturer of wear parts such as impact hammers and other accessories for this equipment. With rich on-site application experience, it can provide personalized customization solutions with the highest cost performance.

For applications involving the shaping of construction aggregates, concrete recycling, and the crushing of cement clinker—all involving medium-hardness materials—Huasheng offers high-performance, cost-effective custom-made impact crusher plates. Drawing on over 300 projects involving cement plants and aggregate materials, Huasheng integrates martensitic steel matrix reinforcement and composite embedding technology to precisely address industry pain points such as rapid wear at the ends of impact plates and reduced shaping efficiency. This approach extends average service life by 2-3 times and reduces crushing costs per ton by over 40%.

Inquiry

Advantage

Raw material control

Customized

Rich experience

Quality inspection

Process

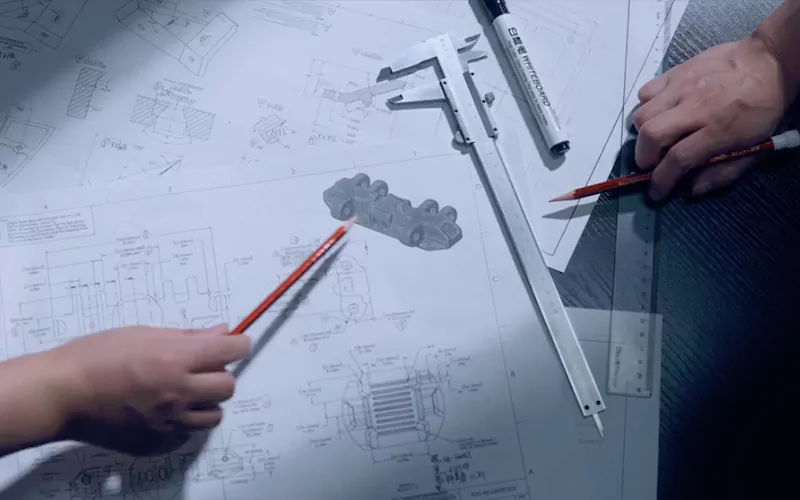

1.Process design

2.Pattern Making

3.Modeling

4.Coating

5.Casting

6.Pouring

7.Clean

8.Heat Treatment

9.Grinding workshop

10.Machining

11.Inspection