Gyratory Crusher Wear Parts

Gyratory Crusher Wear Parts

This translation targets mining/cement equipment specifications, where “gyratory liners” refer to replaceable wear parts in cone crushers. Common material models include:

| Material | Hardness | |

| HS40 | 36CrNiMoV | 375-425HB |

| HS50 | 36CrNiMoV | 475-525HB |

| HS55 | 36CrNiMoV | 525-575HB |

| HS60 | 4Cr5NiMoV | 500-500HB |

| HS65 | Cr15 | >600HB |

| HS70 | Cr26 | >600HB |

Inquiry

Gyratory Crusher Wear Parts are heavy-duty crushing equipment widely used in mining and aggregate industries, renowned for their high throughput, adaptability, and low operational costs. Huasheng, a manufacturer of wear parts such as mantles, concaves, and accessories for these machines, offers diverse material solutions including high-manganese steel, high-chromium alloys, chrome-molybdenum steel, and composite liners. With extensive field application expertise, we provide customized solutions delivering optimal cost-effectiveness.

As a wear solution supplier with 14 years of specialization in mining and aggregate sectors, Huasheng supplies global clients with critical wear components like gyratory crusher mantles, concaves, and crushing shells. We possess in-depth knowledge of material properties (hardness, abrasiveness, clay content) for granite, iron ore, quartzite, and other ores, as well as the distinct wear challenges in primary/secondary crushing applications. Leveraging our multi-material portfolio and 200+ field case studies, we engineer tailor-made wear solutions that maximize service life while achieving the lowest cost per ton – reducing customers’ crushing costs by over 30% on average.

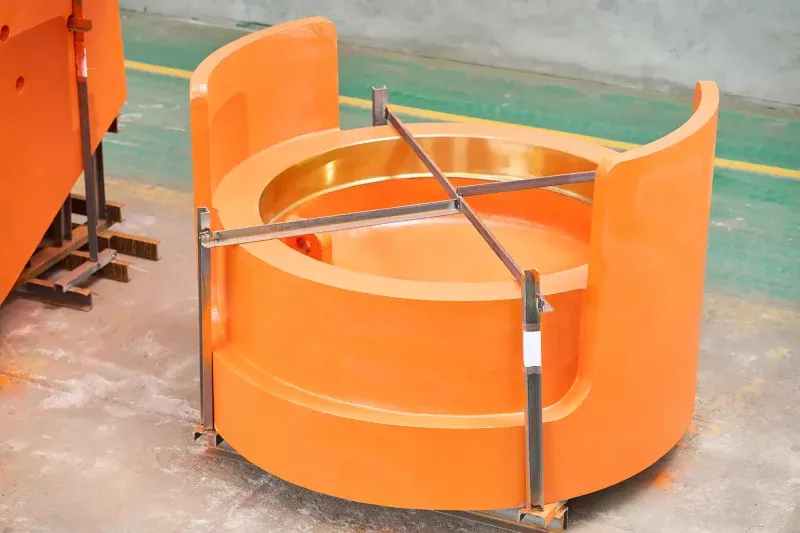

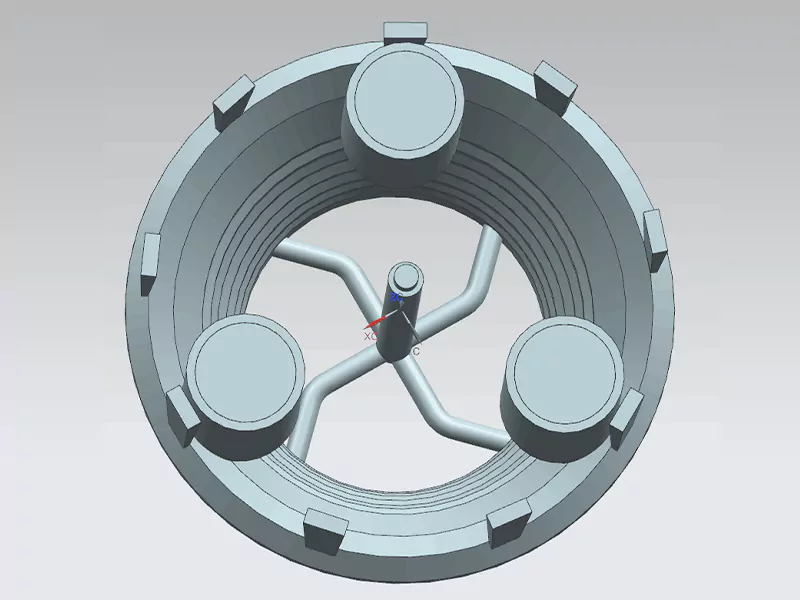

Our Products

Advantage

Raw material control

Customized

Rich experience

Quality inspection

Process

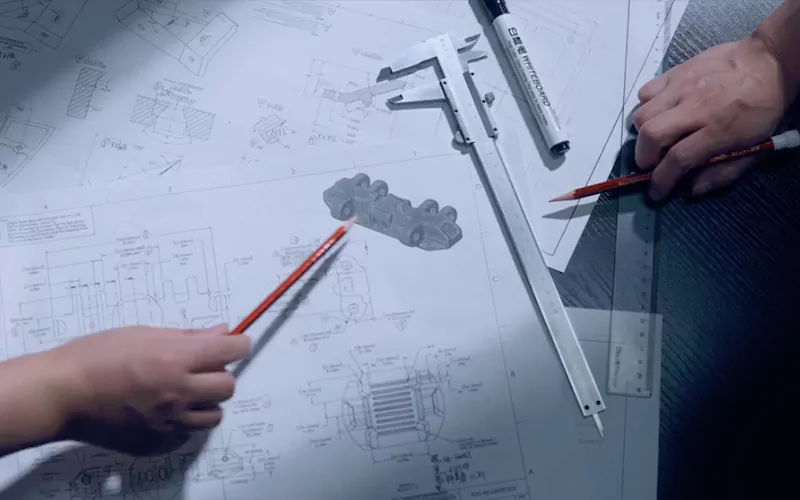

1.Process design

2.Pattern Making

3.Modeling

4.Coating

5.Casting

6.Pouring

7.Clean

8.Heat Treatment

9.Grinding workshop

10.Machining

11.Inspection