Cone Crusher Parts

Cone Crusher Parts

Cone crushers are typically used in secondary or tertiary crushing processes and can handle various ores and rocks, such as iron ore, copper ore, limestone, granite, pebbles, etc. Huasheng is a manufacturer of wear parts for cone crushers and other accessories. The main materials include standard materials such as ZG Mn13Gr2, ZG Mn18Gr2, and ZG Mn22Gr2. With rich on-site application experience, it can provide personalized customization solutions with the highest cost performance. It can also provide composite materials with high manganese steel as the base material, inlaid with titanium carbide alloy rods and ceramic modules.

As a manufacturer specializing in mining crushing wear parts for 14 years, Huasheng provides customized solutions that are wear-resistant and cost-effective for global cone crusher users. For materials such as iron ore, granite, and river pebbles in secondary/tertiary crushing applications characterized by high abrasion and moderate to high impact conditions, we integrate the full range of high-manganese steel substrates from ZG Mn13Cr2 to Mn22Cr2 with composite reinforcement technology. Through over 300 field case studies, we have validated an average extension of liner lifespan by 40-200%, helping to reduce crushing costs per ton by over 25%.

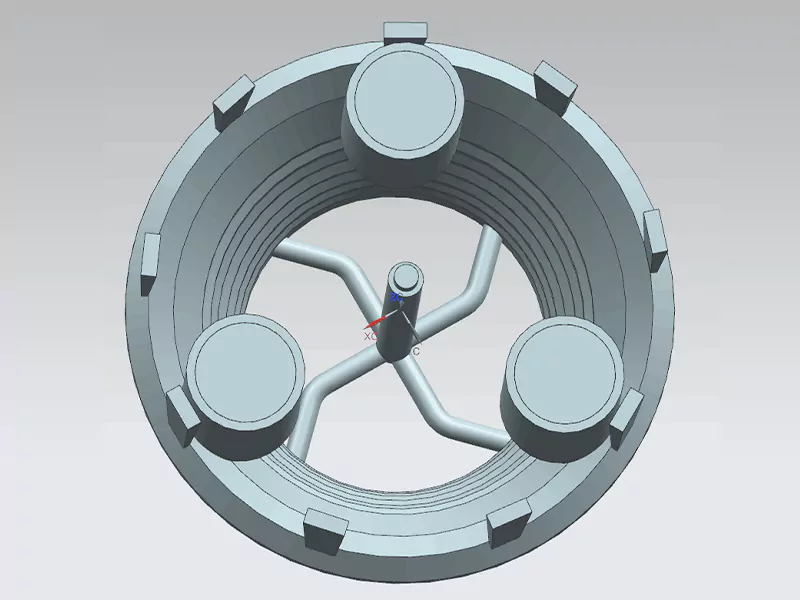

Included in the Huasheng crusher wears offering:

- Mantles

- Bowl liners

- Concaves

- Feed cones

- Main frame liners

- Protection cones

- Arm guards

Inquiry

Advantage

Raw material control

Customized

Rich experience

Quality inspection

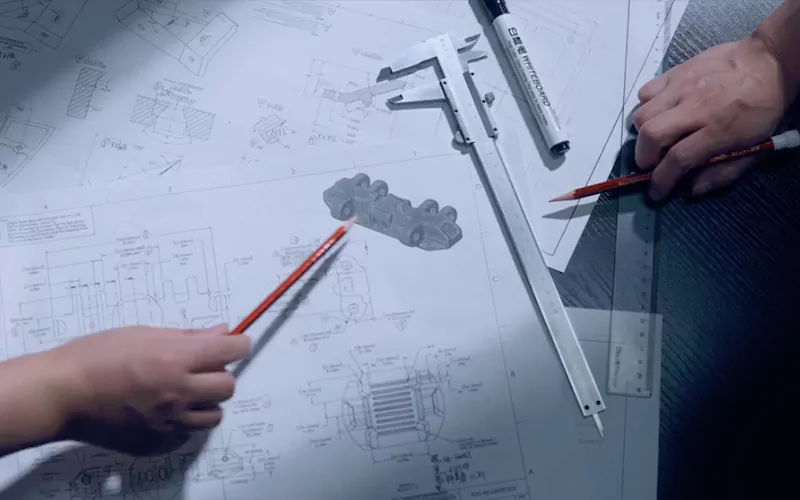

Process

1.Process design

2.Pattern Making

3.Modeling

4.Coating

5.Casting

6.Pouring

7.Clean

8.Heat Treatment

9.Grinding workshop

10.Machining

11.Inspection